This is one of the main problems that arise in the sector, however, there are different mechanisms to effectively counteract them.

This is one of the main problems that arise in the sector, however, there are different mechanisms to effectively counteract them.

by José Tomás Rojas*

One of the most severe problems facing the modern paint industry is bacterial contamination, in particular, the segment that operates with water-based paint systems. The economic losses generated by this type of situation are considerable, in addition to the impact they have on the image of the production company. Nothing more unpleasant for a user than uncovering a container of paint and discovering that it is deteriorated, smelly and degraded in its properties (see Figure 1, next page).

This is in addition to the fact of the discomfort and loss of time caused by having to stop the painting operation, return to the store, place the claim, and wait for all the necessary procedure for the replacement of the paint, or the return of the purchase amount. Faced with these situations, many users simply discard the paint, and change suppliers.

Fig. 1 Paint contaminated by bacteria.

Paint companies are well aware of these problems, and since their inception have taken steps to counter them. For this, the main work tool has been the incorporation of biocides into the formulations. Biocides are additives, which added in small quantities, usually between 0.5 to 1% of the total weight, prevent bacterial growth by preventing the deterioration of the product.

In principle the most commonly used biocides were Formaldehyde, as well as certain organic salts derived from mercury (Phenyl Mercury Acetate). The latter was a very effective product, with a wide spectrum of action on bacteria and fungi, ensuring the protection of the paint, and with a beneficial residual effect on tanks and process pipes, due to the permanence and residual effect conferred by the presence of mercury.

Unfortunately for the paint industry, questions began to arise about the use of mercurial-based biocides and Formaldehyde, due to the effect they could have on the health of users and operators of the paint process. Regulations began to appear that limited, and in many cases eliminated the use of these materials, which forced the shift to other non-mercurial alternatives such as those derived from Isothiazolinones: CMIT (ChloroMethyl Isothiazolinone), MIT (Methyl Iso Thiazolinone) and BIT (Butyl Iso Thiazolinones). These new materials, although they turned out to be very effective (Fast Killing) against bacteria and fungi, did not have the power and residual effect of mercurials, and the consequence of this was the detection of bacterial growth, mainly in the laying of process pipes, in particular in areas with restrictions such as valves and elbows, which has finally led to an increase in pollution problems in paints.

Biofilms

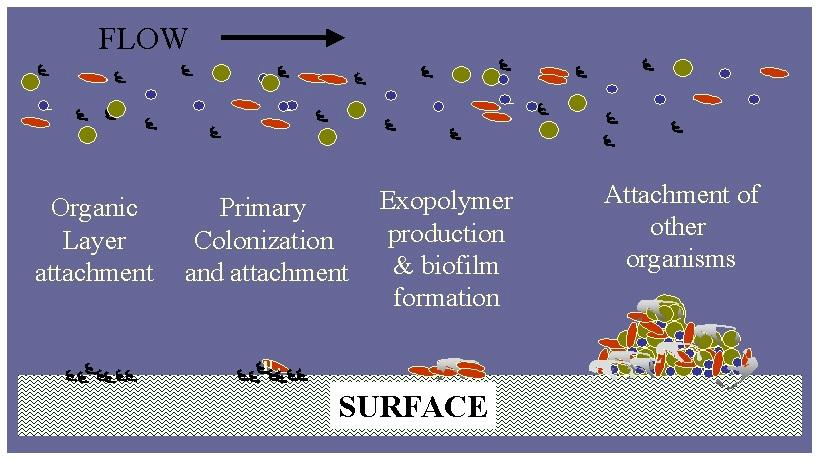

Biofilms are agglomerations of organic matter that are formed by bacterial accumulation and growth (see Figure 2).

Fig 2. Biofilm Formation: Adhesion, colonization, growth, encapsulation.

The preferred site for the growth of Biofilms are the areas where paint residues can accumulate. There are the ideal conditions for bacterial growth such as humidity, temperature, and presence of nutrients, which produces the necessary breeding ground for the reproduction of these microorganisms. When the size of the Biopelicula is large enough, it can detach and enter the flow of paint that is transported to the different stages of the process, causing a punctual contamination, which often cannot be detected by quality controls.

If the focus of microorganisms is not eliminated, contamination begins to appear more frequently, causing a bacterial crisis that forces to increase the doses of biocides in the formulation, which causes costs, and often affectation of the properties of the paints, such as, for example, the alteration in the smell of the paint, that happens to have the smell of the biocide. In more severe cases, biofilms, in addition to contaminating paints, seriously compromise the integrity and functionality of the piping system (see Figure 3).

Fig. 3 Pipe Obstruction by Biofilms.

Plant hygiene

The best way to avoid the formation of Biofilms is the design of a piping system that avoids placing restrictions on the flow of paints that circulates through them. In particular, "dead spots" should be avoided, which are those sections where paint residues can accumulate, once the packaging process is completed. These precautions are taken into account by process engineers, in new plant designs, but they cannot always be implemented in factories whose operation dates back many years, without considerable investment. For these cases you have to go to a Plant Hygiene program that allows you to keep bacterial growth at bay.

Sanitization

A plant sanitization program has two stages: preventive and corrective. The preventive involves the cleaning of pipes, tanks, packaging peaks, hoses, once the manufacture is finished, with special emphasis on the periods that involve a plant shutdown (Weekends, Holidays). In principle, all the components of the manufacturing process are washed, until the water used comes out without evidence of paint. Subsequently, a sanitizing solution is passed through the system, consisting of high-performance biocides, and surfactant elements that can attack the Biofilms and destroy them. Usually the solution in question is left to act for a certain period, usually half an hour, and then collected in containers suitable for final disposal, according to the manufacturer's instructions.

The corrective phase involves the identification and removal, mechanically, of the layers of Biofilms that have formed, and whose size makes them immune to the effect of the sanitizer. Clogged pipe sections should be changed and removed, as well as the replacement of filling spikes and hoses, which show that they have been attacked by biofilm.

More details of all these processes can be obtained by going to the suppliers of the biocides and sanitizing solutions. Normally these have specialized personnel who can provide advice, audit plant hygiene and train staff in all related issues. They are usually available to users, usually at no cost to the paint manufacturer.

* José Tomás Rojas. JTROJAS Pinturas, F.P. You can send your comments to the email [email protected]

Leave your comment