In the result of a good aqueous type paint has a lot to do with the good pH balance. Let's know some aspects to take into account in the formulation.

In the result of a good aqueous type paint has a lot to do with the good pH balance. Let's know some aspects to take into account in the formulation.

by Manuel Chire Sarayasi(1), Oscar E. Chupayo Yauri(2)*

Within the manufacturing process of a paint, there are several factors that can destabilize the product, this destabilization is presented as a decrease in pH and this brings as consequences a malfunction of the additives, generating a film with properties of low adhesion, poor color quality, bad texture, low brightness, procreation of bacteria and consequently a bad smell of the paint. [1]

Interaction of pH with dispersion

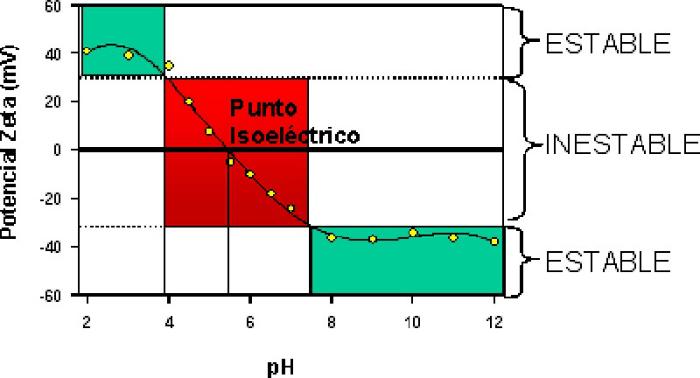

To obtain a good quality paint the pigments must be very well dispersed, and the measures of the zeta potential can be used in this case to control the composition of the paint and the amount of additives needed for optimal dispersion. [2]

The Z potential is the potential difference between the surface of the moving particle and the sine of the solution[3]. The stability of a dispersed system is due to the presence of the electrical layers surrounding all the particles; the mutual repulsion of these layers prevents flocculation.

Simple and inorganic electrolytes can have a significant effect on the zeta potential. In this way it is necessary to identify the appropriate type of alkalizer in order not to add unnecessary ions and maintain the electrostatic stabilization of the dispersion also taking into account the dispersant molecule (steric stabilization) in use. [4] [5]

Thus, the pH becomes an important parameter to control, and this graph shows a typical action of its effect.

Fig. N°1. At the isoelectric point the particles do not experience repulsion, so agglomeration can be an effect to be expected. In fact there may be some attraction near this value as well, and as a rule if we want to make sure that there is repulsion between the particles, we must make sure that the zeta potential value is greater than +30mV. This graph gives us the region of instability in terms of pH, in this case between pH 4 to pH 7.5; And the regions of stability, pH less than 4 and greater than 7.5. [6]

Interaction of pH with binders

The chemistry of paints is intimately linked to filmogenic substances, also often called binders. The main component of this product is an aqueous emulsion consisting of polymers; these polymers form a cohesive film on a substrate and whose function is to properly bind pigments and pavers after drying or curing. [7]

Emulsion polymers are designed in a specific way and have a certain pH. Because the stability of these polymers is closely linked to pH, it depends on the type of polymer to take into account the pH adjustment. In general, all polymers in dispersion have a good stability between 7.5 and 8.5, some such as vilnyl-veova acetate can be stable at pH 5 and even some type of vinyldenum chloride can be stable at pH 1.

In the manufacturing process of the paints the pH must be controlled and at the end of the process it must be adjusted to adequate limits to achieve good stability.

In polymerization processes, the monomers used rarely reach full conversion, so inevitably, residual monomer remains in the polymer. The presence of this monomer is not desirable, due, among others, to its toxicity (such is the case of acrylonitrile or vinyl chloride), whose unpleasant smell (the presence of acrylates and methacrylates, even at low ppm is a big problem in applications such as interior paints), so the stage called redox depletion or post polymerization is necessary. [8]

Aware of this demand, there are developed additives on the market that, quite apart from controlling the pH of the paints, act as anti-odor additives, which when incorporated into the mass of the polymer, accelerate the formation of free radicals; therefore, they decrease the amount of free monomer responsible for the unpleasant odor. [9]

pH interaction with rheological modifiers

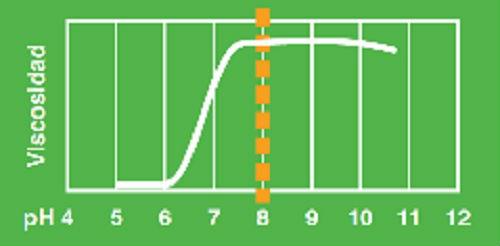

Rheology modifiers are commonly used as they help control the application of the coating and its final appearance. The thickening mechanism will depend on the type of structure that the rheological modifier forms with the latex particles. Each type of modifier has its own characteristics.

To allow good functionality of acrylic thickeners (ASE/HASE) the acid groups in the polymer chains must be neutralized. Typically, the thickened formulation should have a final pH between 8 and 9.5 to ensure optimal thickening efficiency and to maintain a stable viscosity. If a volatile alkali, such as ammonia, is used, care must be taken to avoid alkali loss and pH decrease, as it can lead to reduced viscosity.

Fig. N°2. Increased viscosity in the alkaline pH range thickening the aqueous phase due to the entanglement of polymer chains. [10].

Cellulosic thickeners are also pH dependent and to accelerate the process of hydration and viscosity development it is necessary to raise the pH, between 8 and 9, according to the needs of time in the production process.

Interaction of pH with biocides

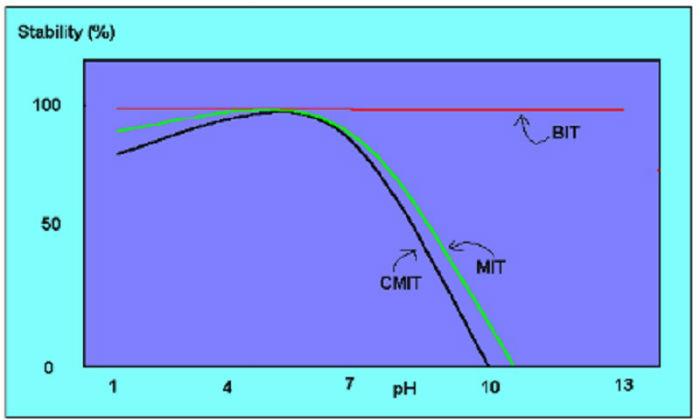

The vast majority of aqueous paints (mainly architectural paints), have all the necessary components for a proliferation of microorganisms to occur, if the pH is adequate (between 5 and 7), organic matter as a nutrient and water, leads to the formation of aerobic colonies (with the presence of air) or anaerobic (in the absence of air), the latter are responsible for the bad smell that occurs when there is fermentation or putrefaction.

One of the factors that affect the functionality of biocides is the pH, for this it is necessary to control it according to the type of biocide selected. Chloromethyl-isothiazolinones are destroyed at pH greater than 9.5 and for this reason many manufacturers adjust the pH to limit values of 9.5. [11]

Fig. N°3. Effect of pH on the stability of each type of biocide. [12]

(1) * Eng. Manuel Chire. Technical Marketing Specialist in Paints & Construction. Disan Perú S.A. You can send your comments to the email [email protected]

(2) * Chim. Oscar E. Chupayo. Technical Marketing Assistant. Disan Perú S.A. You can send your comments to the email [email protected]

References

[1]http://apexperteam.blogspot.com.co/2016/06/pinturas-aqueous-e-measurement.html

[2]http://depa.fquim.unam.mx/amyd/archivero/PotencialZeta_1246.pdf

[3]https://www.uac.edu.co/images/stories/publicaciones/revistas_cientificas/prospectiva/volumen-8-no-1/article9-v8n1.pdf

[4]http://www.edutecne.utn.edu.ar/tecn_pinturas/C-TecPin_VIII_a_XI.pdf

[5]http://ceramica.name/tecnologia_ceramica/Archivos/Defloculantes.pdf

[6]https://www.quiminet.com/articulos/como-help-the-zeta-potential-in-suspension-formulations-and-emulsions-21731.htm

[7]http://apexperteam.blogspot.pe/2015/08/EstabilidadDeResinas.html

[8]https://es.wikipedia.org/wiki/Pintura_acr%C3%ADlica

[9]http://www.paintshow.com.br/paintpintura/noticias/view/1819/polystell_desenvolve_aditivo_que_elimina_cheiro_da_tinta

[10] http://www.dispersions-pigments.basf.com/portal/load/fid797503/BASF%20Rheology%20Modifiers%20Practical%20Guide

[11]http://www.edutecne.utn.edu.ar/tecn_pinturas/A-TecPin_I_a_V.pdf

[12] https://es.scribd.com/doc/56711521/Sistemas-Preservatives-in-The-Paints Industry

Buenos días, Eduardo. Muchas gracias por tu apreciación. Nos alegra que te haya resultado útil. Esperamos seguir dando luces para la confección de productos de calidad a través de nuevos contenidos. Una buena semana.