Heat is an element that is present in all processes associated with powder coating, from manufacturing to application.

Heat is an element that is present in all processes associated with powder coating, from manufacturing to application.

By José Tomás Rojas*

Heat is required to achieve the fusion of the resins that make up the formulation, and thus promote the dispersion of the pigments and additives that constitute it, through the extrusion process.

The spraying process does not require heat, but it produces it, since it is done through the use of mechanical elements that work at high speed.

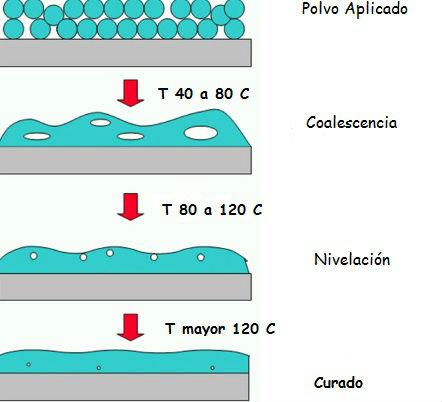

Subsequently, and already in the application stage, heat is required to achieve the processes of fusion, leveling and curing, which will give rise to the paint film as we know it. This stage is indispensable, since the powder applied as such does not present any type of mechanical property or adhesion that can make it useful, in fact, it can be removed from the surface simply by applying compressed air. It is then necessary to provoke the fusion of the same so that, in this state of matter, the wetting of the substrate occurs, the leveling that the decorative finish will generate, and the cross-linking reactions that will lead to the development of adhesion and mechanical resistance properties. (See Figure 1).

Figure 1. Outline of the Leveling and Curing Process. An approximate relationship of the temperatures at which the aforementioned phenomena occur is given.

Cured

In powder coating, when we refer to curing, we indicate that the product is capable of reacting chemically, in the presence of heat, through a polymerization process. These types of products are known as thermocurables, and differ from thermoplastics in that the change that heat produces in them is a chemical change (change of properties), and not a physical change (change of state). In our case, the specific chemical reaction occurs thanks to the presence of functional groups, located within the resins that make up the formulation.

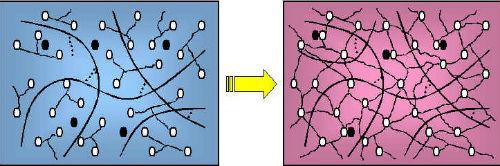

For example, in the case of epoxy polyester products, also known as hybrids, the curing reaction occurs between the epoxy groups of the epoxy resin, and the acid groups of the polyester resin. Thanks to this reaction, it is possible to combine the chains of both resins, creating a three-dimensional, highly criss-cross network, which is what gives rise to the development of the properties that characterize powder paints. This process is irreversible, that is, it is not possible to return to the original state when the application of heat ceases. A schematic idea of what curing is is presented in Figure 2.

Figure 2. Representation of molecular cross-linking, characteristic of curing. The reaction is irreversible.

Curing speed

The curing speed of a powder coating is defined as the time it takes for the product to go from a situation of not curing to a state of 100% cured, and is dependent on temperature. This means that at low temperature the reaction will occur slowly, or even, it will not happen. As the temperature increases, the reaction will start and accelerate with the increase in this variable.

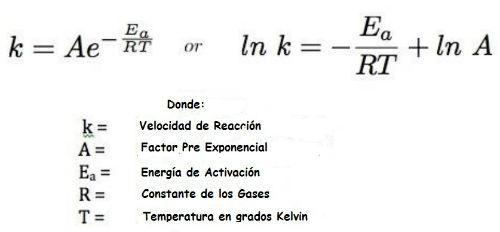

There is a minimum temperature (energy) value necessary for the curing reaction to begin. This energy is known as activation energy and is related to the reaction rate and curing temperature using the well-known Arrhenius equation:

Figure 1.

This equation also indicates that there is an exponential relationship between reaction rate and temperature, which means that small increases in temperature will have a significant effect on the increase in reaction rate.

Conclusions

The previous theoretical study indicates that heat is an important element in the manufacture and application of powder coating, as well as its effect on leveling and curing. The relevant conclusion is that in some processes we need to remove heat, and in others we must apply it. It is also highly recommended that we have at our disposal equipment that allows us to quantify the amount of heat involved, which can be done through the measurement of temperature in the different stages of the process.

During manufacturing any excess heat can cause reactions in the product or pre-cured. This means that cross-linking reactions can occur at low temperature, which impairs the leveling and wetting of the substrate.

This results in poor appearance and problems with mechanical properties. In general, during processing and storage, powder coating should be maintained as soon as possible at temperatures not exceeding 25 degrees Celsius, to prevent low-temperature reactions and maximize its stability. There is a variety of refrigeration equipment on the market that allows to achieve this purpose.

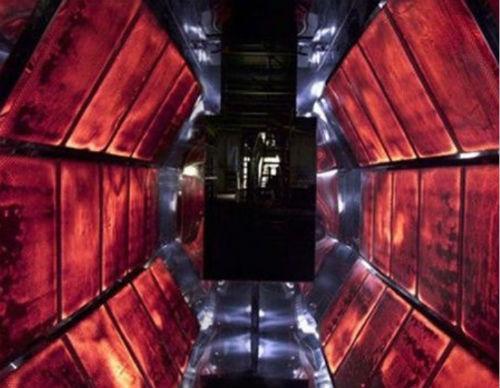

During application, specifically in the baking process, we must provide all the heat necessary for the reaction to take place, and all the properties of the applied film can be developed. Usually the curing curve of the product tells us what is the time and temperatures necessary to which the painted piece must be exposed to achieve 100% curing. (see Figure 3).

Figure 3. Curing oven. Enough heat must be supplied to achieve 100% curing.

If due to problems in the heat supply we do not achieve 100% curing, it is possible that a film with good leveling and appearance will be obtained but that will fail to apply the mechanical resistance tests. One way to determine that there has not been a good curing is to pass the piece through the oven circuit again; if we can show improvements in mechanical failure, we are facing a situation of low curing.

Keep in mind that these curves always refer to the temperature of the metal, and not to the temperature of the furnace. It is advisable to have elements that allow these temperatures to be determined. Usually the technical service representatives of the paint manufacturer have this equipment, and can perform the temperature profile study of the furnace, at the request of the customer.

* Lic. José Tomas Rojas. MSc. President JTROJAS PINTURAS. Email: [email protected] Twitter: @JtrojasPinturas