Original equipment manufacturers (OEMs) turn to custom formulators to solve complex adhesion problems with laminated coils and metal sheets.

Original equipment manufacturers (OEMs) turn to custom formulators to solve complex adhesion problems with laminated coils and metal sheets.

by Unichem*

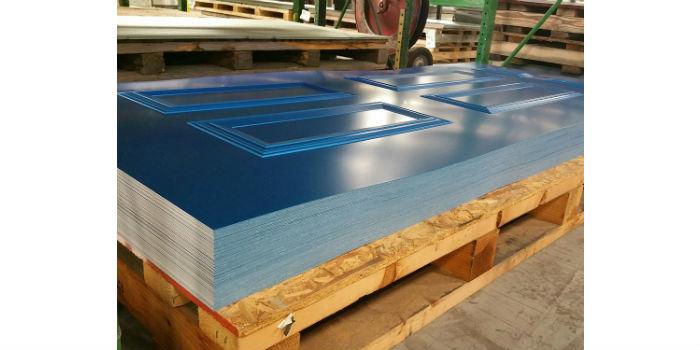

For manufacturers who use steel, aluminum and other flat rolled metals to manufacture parts or products, the possibility of attaching decorative sheets and laminated films to the substrate provides the opportunity to offer attractive finishes that give a competitive advantage.

Among the decorative finishes are the stainless steel look, brushed copper and the appearance and hue of natural wood, as well as a wide variety of colors, marks and degrees of gloss. Laminated films can also serve a functional purpose, providing resistance to scratches or chemicals.

However, the lamination process on metals can have countless complications. If the wrong adhesive is used, if the curing process is not precisely controlled, or if many other variables are not controlled, the result can be a large amount of waste or parts that fail at the installation site.

When this occurs, OEMs and even coil processors that supply them with untreated or stage B coils (to which an adhesive has been previously applied) turn to custom formulators for unique solutions to production problems.

In many cases, the right adhesive formulation can have significant benefits, such as speeding up production, removing waste material, reducing the amount of material required, and even improving corrosion, UV, and antimicrobial resistance.

Options for applying the laminate

The use of flat rolled metal to manufacture parts or products is very common throughout the manufacturing process. Some of the most common applications are household appliances (refrigerators and freezers, washing machines, dishwashers, microwaves, extractor hoods), construction products (insulated wall panels, garage doors, roofing products), and mobile and prefabricated home markets (walls, door panels).

The process of adhering the laminates to rolls in coils or to the plates is carried out in different ways.

Manufacturers can employ in-house staff to spray or brush adhesives within the manufacturing plant. However, this process is slow, labour-intensive and raises safety and environmental concerns. Quality can also be an issue and waste rates are usually quite high.

Automated equipment can also be used to apply sheets and films to flat rolled metals that come with B-stage adhesive (pre-applied) and are supplied by the coil processor. This type of adhesive is designed to activate and cure within a specific temperature range. The laminate is then applied to the coil at the manufacturer's plant using furnaces and pressure rollers.

Although automated processing is much faster and more efficient, it can also lead to quality control issues due to temperature variations within the curing furnaces that are part of the process. In some cases, waste rates can reach 20%.

"Applying adhesives in the final manufacturing plant can produce significant amounts of waste, higher labor costs per part, and can expose the manufacturer to considerable environmental costs and regulations," says Eric Fossen, CEO of Spencer Ridge Consulting of Ontario, Canada. "So, manufacturers are typically looking for a more efficient solution that gives them more consistent [laminated] performance."

Fossen, who serves as a consultant to the coil processing industry, says the simplest solution for OEMs is typically to outsource the entire process. In this way, internal labor, application equipment, curing furnaces and environmental control facilities are no longer necessary.

Adhesives applied in a coil coating operation offer the advantage of a high degree of consistency in both film thickness and curing conditions, which can provide a stronger and more durable adhesive bond. The high-quality application allows to give different shapes to the product after lamination, including curved and rigid shapes, without affecting the integrity of the bond between the adhesive and the film.

Adhesive quality

Although coil processors more rigorously control the application process, the quality of the joint ultimately depends on the type of adhesive used.

According to Fossen, many adhesive manufacturers offer a wide variety of standard options, but do not customize a product to meet the specific requirements of a given customer, unless they are very large volumes.

"In the case of large adhesive suppliers, if they have a product that works, wonderful. If not, they are usually not willing to adjust the product to suit a certain application," says Fossen.

When this happens, coil processors and even OEMs turn to custom adhesive formulators with the experience and knowledge about coil processing needed to find unique solutions that solve difficult problems.

Concrete example – Door panels

For Elixir Door Company, the development of access doors for prefabricated houses involved the use of vinyl-coated steel that was stamped and formed before being filled with polyurethane foam to give insulation and structural strength.

To achieve this, Elixir Door ordered rolled steel into coils to which stage B adhesive had previously been applied. The vinyl was then applied using curing furnaces and pressure rollers in the manufacturing plant.

However, about 2 or 3 years ago the company began to experience significant adhesion problems that produced a high rate of waste.

"Vinyl was coming off in alarming dimensions, not just a little here and there, but in many places. It was very inconsistent," explains general manager Archie Brown.

Unable to pinpoint the reason, Brown says he called in a custom adhesive and coating formulator, Universal Chemicals & Coatings (Unichem). The company specializes in coil processing and can create custom adhesives and coatings.

The solution consisted of an adjustment of the temperature parameters of the curing furnace, as well as a custom-formulated adhesive designed to cure within a wider temperature range.

"Unichem analyzed our entire process and took some corrective actions," Brown says. "We adjusted everything and we haven't had any problems since."

According to Brown, Elixir Door subsequently decided to outsource the entire process. Now, the coil processor delivers a finished, vinyl-coated part using Unichem's adhesive formulation that already has the right dimension and stamped in the right shape.

"We were paying [the coil processor] to apply the adhesive, then we paid to apply the vinyl in our facility. Now, they do everything in a single operation at their facility. So, our costs are much lower and we don't have to worry about waste because now they are the ones who take care of it," says Brown.

Concrete example - ceiling plates

Unichem has also developed a B-stage adhesive used to bond metal plates to PVC membranes. The plates are fixed to the roof platform and then activated by heat to attach them to the membrane, creating a permanent and very water-resistant roof.

Stage B adhesive is initially applied to metal substrates using a continuous line of coil coating. The adhesive-coated coils are then stamped onto the finished plates.

To create the ideal adhesive, Unichem had to meet a large number of physical performance criteria, such as resistance to outdoor exposure, rapid activation cycle and good strength of both the initial and aged adhesive.

From black to white

According to Fossen, even minor formulation changes in strength of both the initial and aged adhesives can improve the final product. He cites the example of a customer who wanted to use the same adhesive, but changed it from black to white so that it wouldn't be noticed if the laminated film was scratched at the installation site.

Unichem was able not only to create a white adhesive, but also to expand the range of the curing temperature.

"Unichem is unique in its ability to take a set of performance criteria and formulate an adhesive to meet the requirements," Adds Fossen.

* More information at Unichem - Email: [email protected] - www.unicheminc.com

Leave your comment