By Vanesa Restrepo

The benefits of nanotechnology for the paints and coatings sector is undeniable. To date, great strides have been made in coatings that, for example, self-regenerate and save a lot of money on small automotive repairs. There are also known cases of coatings with nanoparticles that allow maintaining certain thermal conditions in the place where they are applied, reducing the use of air conditioners or heating systems and, consequently, the consumption of energy and refrigerants that affect the ozone layer.

Every day news about new nanotechnological findings linked to coatings flood the press, both massive and specialized, but most of them come from the United States or Europe, and most of them are not yet commercialized.

If we look at the development of nanotechnology research in Latin America, we can see a clear relegation, especially in the private sector. Some of the largest manufacturers in the region, which are characterized by investing large sums of money in research and development of new formulations, confirmed to INPRA LATINA that the technology transfer process has taken longer than it should, so even the offer of this type of products is insipent.

According to Juan Manuel Álvarez, NACE representative in Colombia, and consultant in aeronautical and aerospace coatings, the technology has arrived gradually, but it is not yet of mass application. The engineer confirmed that working with ceramics, where nano polishing and nanoapplication are worked, especially in the turbines of the 787 Dreamliner type aircraft, is the most common procedure.

This type of technology provides greater reliability, greater corrosion control and better adhesion, but the cost and ignorance of the advantages and the way of application makes advances in the matter slower.

To this is added the lack of investment in research and own development of products, so there is an almost absolute dependence on European and North American universities and research centers, as well as on the technology transfer of multinationals with a presence in Latin America.

Know how

The director of research and development of new products in the main paint formulation company in Peru, Corporación Peruana de Químicos -CPPQ-, Jaime Baldeón, explained that in the Latin market products with nanotechnology are not yet commercialized, "in fact, we know them from the experience of the United States. USA and Europe".

For him, the technologies that will arrive first are the ones that have the most booming in these markets; that is, self-repair coatings. "Unfortunately because of the technology transfer and know-how, manufacturers are still researching and seeing how to implement them."

Contrary to what many think, Baldeón supports the idea that the most expensive thing is not the implementation of technology and equipment in general, but that high costs come with knowledge. That is, the patents and know-how that make the knowledge of the process, some formulations and even inputs to apply nanotechnology to paints, are mostly the exclusive property of some companies.

Real developments

In addition to automotive and aeronautical coatings, the region is beginning to see advances in the area of marine paints. Specifically, the modification of silicon-based polymers, polysiloxanes, to which titanium dioxide nanoparticles are incorporated, as well as calcium carbonate in nanometric proportions, has been seen.

As a result, an absorption of UV radiation is obtained that converts Nox into nitric acid, which causes polluting particles or scales of marine organisms to be eliminated, so that the surface will be self-washable with rainwater or seawater, without residues, since the calcium particles neutralize the acids generated.

Traditionally, biofouling has been controlled with special paints containing compounds that are toxic to the responsible organisms. However, current regulations require that biofouling paints are not harmful to the environment, so more environmentally friendly ways are being sought to prevent marine organisms from adhering to the hull of ships.

This development was conceived in Europe and was reviewed by New Scientist in 2004. Later in Latin America, the possibility of implementing this development in the merchant fleet of countries with great naval development such as Chile, Peru and Mexico was studied.

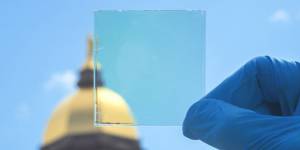

This type of coatings, which are innovative and also serve for the evaluation of decontamination, have also been developed in the field of architectural paints. In this segment, a solution is sought to prevent external surfaces from getting dirty and stained, a phenomenon that has been exacerbated by the air pollution of recent decades. The dirt on the facades has an impact on the quality of the urban environment and on the life cycle costs of the buildings.

The team that developed the project told the magazine, at the time, that the project uses titanium dioxide photocatalysis to develop innovative materials that have properties against dirt and pollution and that can be applied to facades.

Looking for the advances

The hope of own developments with nanotechnology comes on account of one of the most common materials in the industry, titanium dioxide, whose nanoparticles are being processed to obtain paints more resistant to attacks by fungi and bacteria, as well as for the creation of self-cleaning and self-regenerating coatings. But, as with previous technological advances, this one is not yet well known among our entrepreneurs.

However, we must bear in mind that our own development will take us a few more years, considering that we are several years behind in this technology, compared to the world powers, and that the investment capacity of local companies is more limited. There is also a need for clear interest from end-users, such as airlines and shipping companies, to ensure that the money invested in one's own research will be recouped in a short time and marketing efforts should not be greater than those of a traditional paint line.

Similarly, it is necessary that multinationals begin to bring to their subsidiaries in Latin America some of these innovations, so that they begin to create a market and encourage local producers to compete in these new segments.

Associations of manufacturers and applicators are also in the duty to come together to seek legislation that encourages the advancement of research and development of new products with nano technology. And finally, new alliances between universities and the private sector will have to be sought. Experience in the corrosion and high-performance coatings sector shows us that this is the fastest and most cost-effective way to approach new technologies and generate our own research that generates tangible and good performance products.

The advances are just around the corner and their benefits are already known to all. Now it is necessary for companies to unite and reach it, to be able to incorporate it into our day to day, creating a new market for them and great benefits for end users who will have better quality and cutting-edge technology withoutThe hope of own developments with nanotechnology comes on behalf of one of the most common materials in the industry, titanium dioxide, whose nanoparticles are being processed to obtain paints more resistant to attacks by fungi and bacteria, as well as for the creation of self-cleaning and self-regenerating coatings.

However, having our own development will take us a few more years, considering that we are several years behind in that technology, compared to the world powers, and that the investment capacity of local companies is more limited. There is also a need for clear interest from end-users, such as airlines and shipping companies, to ensure that the money invested in one's own research will be recouped in a short time and marketing efforts should not be greater than those of a traditional paint line.

Similarly, it is necessary that multinationals begin to bring to their subsidiaries in Latin America some of these innovations, so that they begin to create a market and encourage local producers to compete in these new segments.

Associations of manufacturers and applicators are also in the duty to come together to seek legislation that encourages the advancement of research and development of new products with nano technology. And finally, new alliances between universities and the private sector will have to be sought. Experience in the corrosion and high-performance coatings sector shows us that this is the fastest and most cost-effective way to approach new technologies and generate our own research that generates tangible and good performance products.

The advances are just around the corner and their benefits are already known to all. Now it is necessary for companies to unite and reach it, to be able to incorporate it into our day to day, creating a new market for them and great benefits for end users who will have better quality and cutting-edge technology without having to look for it outside their cities. having to look for it outside their cities.

Leave your comment