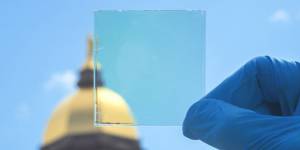

The industrial sector requires that special coatings that thermally insulate be applied to many of the surfaces located in the plants. We present a technological advance on this class of products.

The industrial sector requires that special coatings that thermally insulate be applied to many of the surfaces located in the plants. We present a technological advance on this class of products.

by Adexim*

For decades, industrial chemical companies, as well as others like them, sought a thermal protection of easy application for the protection of forgotten surfaces in the processes, so that there was no aggression to their operators and / or workers in contact.

Several systems were created in all those years, always of high added value and based on systems that often demanded solubilization with organic solvents that from another place could cause a fire during the application process.

In Germany, the engineer Joachim Müller, a specialist in industrial coatings, engaged in the laboratories of Worlee Chemical GmbH, worked on a project for almost eight years seeking to enable a formulation of a high-safety coating, dispersed in water, that could offer a necessary protection and solubility in water with an easy application process.

For Eng. Muller the basic idea was defined since the chemical and physical characteristics of the raw materials were achieved and were involved as he imagined.

The first phase was to get Worlée herself to buy the idea. As well as the vote of confidence of the team and with the consent of Worlée, the technicians were investigating and forming an acrylic dispersible in water and that could have the characteristics foreseen in the project.

You should have at least:

-High solids

-PH about 6

-Specific weight, in the maximum of 1.06 g7 cm3

-Freeze protection

-And the most difficult: the incorporation of Enova Aerogel that was an important part of the project.

Demand

The greatest demand at the beginning of this development was related to the isolation of the higher heating parts of the partially internal engines inside the cabins of huge long-haul trucks, which greatly mistreated the driver for long hours, mainly in summer times.

Many stages had to follow to develop some systems of resins dispersible in water and compatible with the idea, which could also absorb the protective materials defined for the project.

Thus, the system was theoretically prepared to work with the following characteristics:

1.La necessary incorporation of Enova Aerogel in the planned proportion.

2.Application in Mono component systems.

3.High elasticity even at low temperatures.

4.Excellent adhesion on various substrates.

5.Contact on highly hot surfaces without harm to users.

6.Product with flame retardant additive.

7.Corrosion protection.

Now the birth of what was conventionally decided to call: Worlée Shield was scheduled

In the tests, despite having obtained excellent results, it was found that some additives could bring many benefits to the system. Thus many more properties were developed such as the following:

1.Adjustment of the rheology to allow the application with brush, spatula, or agitation (spray) with the development of equipment for this type of applications.

2.Special addition of a flame retardant that was also developed by Worlée exclusively for that project with the necessary characteristics and total exemption from Halogens (Worlée ADD FR 5000) (Specifications at the end of the text).

3.Another Worlée additive was applied in the system, operating as a corrosion inhibitor for cases where there could be application on any more sensitive steel sheet. This included the formulation of Worlée ADD 8905 (specifications at the end of the text)

4.The drying in the environment (air) of external dispensing equipment.

5.Low thermal conductivity.

6.Total exemption of solvents.

7.No classified as a "Dangerous Product".

8.Another additive is intended in the formulation as structure protection, i.e. an addition of technical glass fibres or flakes compatible with the system.

From the market

In field tests they were compared with several thermal insulation systems (although not dispersed in water), but that in their specification had other thermal insulators with high application costs, more aggressive raw materials, high-cost rock fabrics, ceramic or glass spheres, aluminum profiles, mold preparation and special profiles for molded insulators, high costs in transport and facilities:

1.Without a specific thermal insulator.

2.Coatings with hollow ceramic spheres.

3.Coating with hollow glass spheres.

4.Molded insulators.

5.WorleeShield coating added with Enova Aerogel.

Among many tests, in some we have observed the following result in terms of isolation:

The applications were made in many different substrates and in differentiated equipment systems. So it was tested, at least, with greater intensity in the following applications:

Chemical industry

1.Pipe.

2.Reactors.

3.Thermal storage in tanks.

4.Thermal power plants.

5.Atomic plants.

6.Safety coatings.

7.Distilleries.

8.Steam transport.

Transport

1.Locomotives.

2.Subways.

3.Large trucks.

4.Tractors.

5.Containers.

6.Submarines.

7.Cargo and passenger vessels.

8.Steam-powered machinery room.

Civil construction

1.Refrigerators.

2.Thermal insulation in general

3.Temperature-controlled product tanks.

One of the elements that forced the Worlée technical team to do a great job was to shape the coating characteristics so that in their application they did not demand high costs, as in applications of pre-molded parts with large transport, installation and maintenance costs.

Initially, great ease of application was obtained by brushes and / or spatulas, which was quickly absorbed by applicators in parts of more difficult access, such as the interior of large trucks, tractors and other industrial facilities.

The next challenge was solved with the participation of the German company "Krautzberger", a specialist in spray application technology.

The new participant was developed within their systems with special equipment in two versions that are known as PK 20S AND PK 40D. According to the application needs of each user.

For more information about the system, you can contact the company Adexim at the email [email protected]

Note: Specifications of the products mentioned above: WorleeCryl CH-X-2158, WorleeCryl CH-X-2159, WAdd FR-5000, WAdd 8905 and PK 20S e PK 40D.

Leave your comment