A review to highlight some of the most important innovations in the use of inactive pigments. In this second part, the use of pigments type "Hollow Spheres" and the use of Diatomaceous Silicas (diatoms) will be developed.

A review to highlight some of the most important innovations in the use of inactive pigments. In this second part, the use of pigments type "Hollow Spheres" and the use of Diatomaceous Silicas (diatoms) will be developed.

by M.Sc. Ph.D. Julián A. Restrepo R.*

After the first art of this article that referenced some innovative ideas of paint and coating manufacturers to optimize raw materials. Inactive pigments were mentioned and the main novelties in their use as rheological modifiers, type Bentones, now the use of pigments type "Hollow Spheres" and Diatomaceous Silicas (diatoms) will be unleashed.

2. Use of pigments type "Hollow Spheres": We say that a pigment is active when it has the property of providing color and opacity (covering power) to a painting [6], while inactive pigments fail to provide color or opacity to the paint [2]. Strictly speaking, the concepts of PVC (Volume Pigment Concentration) and CPVC (Critical Volume Pigment Concentration) come into play here, since both constitute the fundamental formulation parameters that allow us to understand the importance and influence of the presence of air in the coating system: At PVCs above the CPVC, there is the presence of air in the coating film, air that is housed in random and irregular spaces. The presence of this air increases the porosity of the coating and the permeability of the film, but in turn increases the dry coating. Thus, an inactive pigment can contribute to the covering of PVCs near or above the CPVC (critical PVC) [2].

On the other hand, the white opacifying pigment par excellence is titanium dioxide [7], which is somewhat expensive, especially when compared to the other inactive pigments usually used to reduce costs (kaolins, talcs, calcium carbonates, among others) [2]. Therefore, when we want to lower the formulation costs, we find that in the pareto, the raw materials that have the greatest impact, usually, are the resin and the active pigment, in this case, titanium dioxide. Therefore, to lower the cost without affecting the coverage, what have been called "Titanium dioxide extensions" or functional substitutes for titanium dioxide are used.

Thus, some of the applications of the "Hollow Spheres" in coatings are: a) reduction of the consumption of titanium dioxide in the paint, through the replacement of part of it by pigment in the form of "hollow spheres". In this case, what this pigment does is imitate the optical effects of titanium dioxide in whiteness and opacity, but using a more economical raw material; b) air is a good insulator and include air (or other gas), in the coating film allows to formulate a coating with insulating properties, which allows to reduce the consumption of air conditioning, for example, if you think about its use for the so-called "cold ceiling paints" or "thermo-regulating paints"; (c) as an acoustic insulator, by allowing the absorption of sounds or noise, by constituting a gaseous barrier within the coating, by providing a "less massive" coating; (d) reduction of the weight of the coating films, without affecting the final covering. Of particular importance in aerospace paints, to reduce fuel consumption and not affect the weight of the aircraft; e) to reduce the cost of painting through a decrease in the density of liquid paint, since including "hollow spheres" in the paint lowers the final density of the coating and therefore the final costs of it.

We will briefly discuss two of the most commercially known applications of pigments in the form of "Hollow Spheres":

a) Use of "Hollow Spheres" as extensions: In 1982 and after 8 years of research [8], the polymer manufacturer Rohm and Haas (today, Dow Chemical), introduced the revolutionary concept of "hollow spheres" in its product Ropaque®, which suggested the brilliant idea of including air in the coating, but "air in a controlled and encapsulated way", through air bubbles, and nothing better than doing it through a "smart polymer" and they developed the first synthetic pigment formed by "rigid hollow spheres".

This "intelligent polymer" is considered an opaque polymer, because in dry, it provides covering, then behaving like a pigment. That is, although the opaque polymer is a synthetic resin of organic origin, it behaves in the coating as an inorganic pigment, hence it can also be considered one of the first "intelligent polymers".

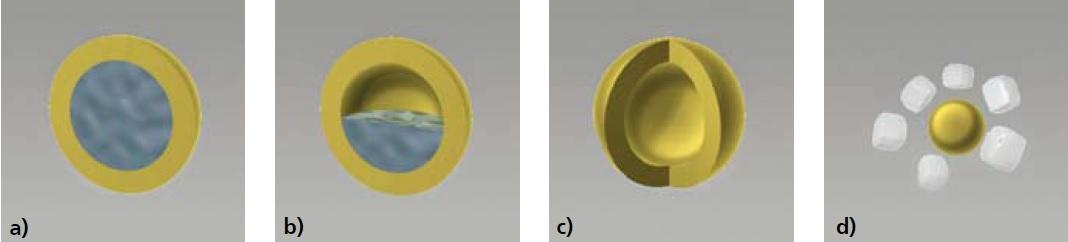

Figure 3 explains how the opaque polymer works: Keep in mind that the polymer shell is permeable to water (it lets it out, but will not let it in anymore), and once the internal water has come out, it is replaced by air and the shell will remain as a rigid sphere, embedded in the resin, together with the other pigments of the pigmentary system. That is, it will behave like another pigment, spherical in shape. This is the key to its operation: Despite being a resin, it will not deform during the film formation process, nor will it present coalescence like the other resin particles present. In addition, this type of particles do not have a tendency to oil absorption (OAI), and on the contrary, they will provide a small resin content, although not film-forming (but that would constitute solids). Not to forget, that because, considering its polymeric nature, its particle size is very small (0.4 um) and works well as spreading titanium dioxide.

Figure 3. Operation of the opaque polymer: a) The polymer shell contains water; b) during drying, water is replaced by air; (c) the inner part of the polymer shell is completely filled with air; d) the resulting hollow sphere is opaque in nature (Images taken from ref. 8).

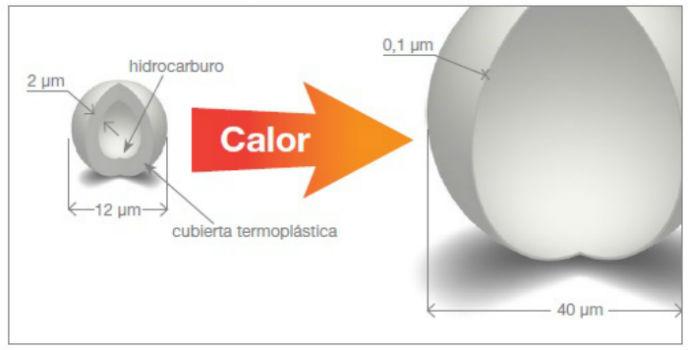

b) Use of "Hollow spheres" for thermo-regulation: For its part, in the early 90s and in the same line of research, the manufacturer Akzo Nobel introduced the concept of "hollow plastic spheres", as blowing agents for the plastics industry, although later they have found multiple applications, including for the paint industry[9]: Expancel® microspheres are small spherical plastic particles (20-150 um), sensitive to heat, which consist of a polymer that encapsulates a gas. Figure 4 explains how "hollow plastic spheres" react to heat: When heated, the internal pressure of the gas increases and the thermoplastic shell softens, resulting in a drastic increase in the volume of the microspheres. The gas remains within the spheres. This ability to contain a significant volume of gas is a very important advantage, for example, in the formulation of thermo-regulating paints, or paints for the regulation of heat or temperature, since the volume contained in the spheres acts as a thermal insulator.

Figure 4. The process of expansion of Expancel's® microspheres in the face of heat, resulting in a drastic reduction in their bulk density (typical values range from 1000 to 30 kg/m³) [Images taken from ref. 9].

Expanded microspheres are easy to compress, when pressure is released, the microspheres regain their original volume. Microspheres are marketed expanded and unexpanded, in wet or dry format, or as masterbatch, and have expansion temperatures in the range of 80 to 230°C [9].

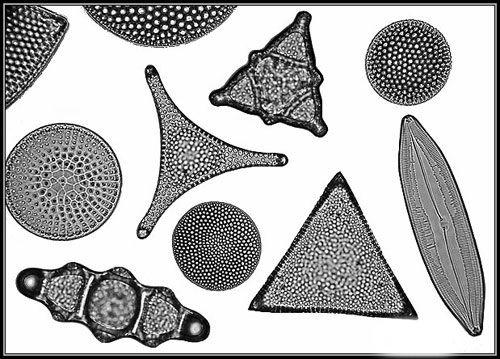

3. Use of Diatomaceous Silicas (diatoms): Diatoms are a class of unicellular algae that constitutes one of the most common types of phytoplankton (tiny aquatic plants) [10]. In the case of the so-called Diatomaceous Silicas, Diatomite, Diatomaceous earth or organic silica, these are the natural skeletons from the fossilization of Diatoms (in the form of silicon dioxide, SiO2), which lived and multiplied in prehistoric waters that covered vast regions of California (United States) and Jalisco (Mexico) [11].

Through the ages (about 30 million years ago), when they died, the skeletons (shells) of diatoms were forming large deposits on the ocean floor. Today, hundreds of large deposits of diatomaceous earth are found all over the world. Some are still underwater and some others are at the bottom of ancient dry lakes. It has been estimated that one cubic inch of diatomaceous earth can contain up to 400 million shells [12], and they are characterized by their high purity and by the almost infinite variety of shapes and sizes that these prehistoric skeletons present. The idea of the use of this material as an inactive pigment (either as a matting agent, loading or spreading titanium dioxide) is highlighted here, and that it presents exceptional forms (as can be seen in Figure 5), which are not found in other inert pigments. What also allows us to think about its proper use could provide mechanical advantages to the coating, only based on its shape. Commercial examples are in the Celite® brand of the company World Minerals.

Figure 5. Diatomaceous silicas have exceptional forms, not found in other inorganic pigments [Images taken from ref. 12].

References

[1] a) Restrepo, J.A., "Anécdotas de la historia de las pinturas, parte I". Inpralatina, Vol. 19, No. 2, Mar/Apr 2014 pp. 16-20; b) Restrepo, J.A., "Anécdotas de la historia de las pinturas, parte II". Inpralatina, Vol. 19, No. 3, May/Jun 2014 pp. 15-18; c) Restrepo, J.A., "Anécdotas de la historia de las pinturas, parte III". Inpralatina, Vol. 19, No. 4, Jul/Aug 2014 pp. 19-22.

[2] a) Restrepo, J.A., "Inactive pigments in formulation. Part I." Inpralatina, Vol. 17, No. 1, Jan/Feb 2012, pp. 21-25; b) Restrepo, J.A., "Inactive pigments in formulation. Part II". Inpralatina, Vol. 17, No. 2, Mar/Apr 2012, pp. 18-21; c) Correa, G. and Orrego, J., "Minerals are metallic in the coatings industry". Inpralatina, Vol. 4, No. 4, August/September 1999, pp. 20-26

[3] Karakaya, M.C.; Karakaya, N.; Bakır, S., "Some properties and potential applications of the Na- and Ca-bentonites of ordu (NE. Turkey)". Applied Clay Science, 54 (2011), pp. 159-165

[4] https://en.wikipedia.org/wiki/Bentonite

[5] Rheology Handbook by Elementis Specialties, 2005.

[6] Restrepo, J.A., "New developments in pigments". Inpralatina, Vol. 14, No. 1, January/February 2008, pp. 28-33

[7] Restrepo, J.A., "Titanium Dioxide: Give Your Application the Ideal Pigment." Inpralatina, Vol. 10, No. 1, Jan/Feb 2005, pp. 22-23

[8] (a) http://mattorourke.net/samples/dow/ourstory/innovation_revolutionizingpaints.htm ; b) http://coatings.dow.com/en/products/ropaque#history-of-hiding

[9] (a) https://www.akzonobel.com/expancel/system/Images/AkzoNobel_Expancel_Short_introduction_ES_tcm65-75515.pdf; (b) https://www.akzonobel.com/expancel/system/Images/AkzoNobel_Expancel_Multiperformance%20additive_ES_tcm65-91989.pdf; (c) https://www.akzonobel.com/expancel/system/Images/AkzoNobel_Expancel_The_art_of_microspheres_tcm65-72368.pdf

[10] https://en.wikipedia.org/wiki/Diatomea

[11] http://www.quimicuy.com.ar/folletocelite.pdf

[12] http://dietasparabajardepeso.co/tierra-de-diatomea-silicio-organico/

* Julián A. Restrepo R. is an Advisor and Technical Consultant in Coatings CoatingXPERTS. [email protected] Medellin, Colombia.

Leave your comment