M will address different important aspects to execute a correct design of a specification of anticorrosive coatings.

will address different important aspects to execute a correct design of a specification of anticorrosive coatings.

by Eng. Nicolás F. Oriundo De la Cruz*

Currently, many of the investment projects, whether public or private, that are developed in Latin America carry with them a technical specification; This document aims to give the necessary guidelines to protect and conserve the fixed assets of a company, be it manufacturing, hydrocarbons, energy, etc.

But if the technical specification of the project is not properly designed, it can generate problems during the course of time that may take the development of the same, leading to delays, stoppages of works, extraordinary meetings due to differences in interpretation, etc. Generating economic losses not only to the contracting companies, but also to the end user who sees his project delayed by difficulties like these.

Photo 1: Failures in the coating application work often originate from an underdeveloped technical specification. Such a lack of definitions can lead to conflicts over the scope of work and what it requires to be acceptable within the quality time frame.

Due to the importance of this document, that is why, for a good design of a technical specification of coatings, the ideal is to develop long-term atmospheric exposure tests and with various protection systems that must be installed in the same place where the structure would operate. In this way the durability of the coating system could be obtained with a high degree of confidence.

But, since these types of long-term tests are not carried out precisely because of the time required and also because the selection of the protection system itself is not made in advance, but they do it at the moment. In such circumstances the alternative option that can be made is to look for technical recommendations, based on the experience of other professionals and that are reflected in norms, standards, articles, among others.

That is why every professional who needs to develop a technical specification of coatings should know the following basic criteria for the design of this document:

1. Classification of Environments

2. Estimated time of structure protection

3. Design considerations

4. Types of surfaces and surface preparation

5. Selection of the coating system

Classification of environments

As we know, approximately almost 80% of structures are exposed to the atmosphere, and most of the material losses due to corrosion correspond to atmospheric corrosion.

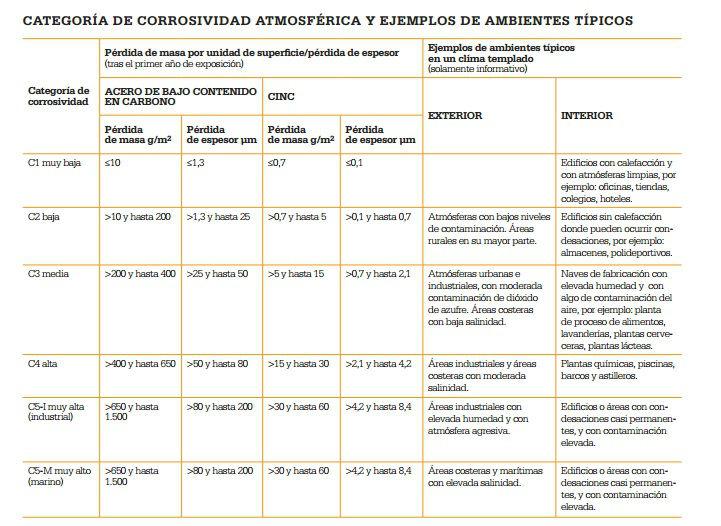

That is why, the first step that must be considered to design a technical specification of coatings is to identify the atmospheric environment in which the structure will be in service, a document that can help us for this case is ISO 12944-2 in which it establishes five categories of atmospheric corrosivity that are detailed in table No. 01.

Through this table we can compare the characteristics of our environment and identify what type of category we are in, so that we can have an idea about what type of environment the project is going to be developed.

Photo 2: The first step to consider in designing a technical coating specification is to identify the atmospheric medium in which the structure will be in service.

Remember that understanding your environment can help custom specifications, ensuring that your selected coatings are not less or larger than specified and therefore, that it helps you in saving unnecessary costs in the future.

Estimated time of structure protection

Once the type of atmosphere in which the structure will be subjected has been identified, we proceed to define the time required to protect the structure until its first major maintenance in that environment. ISO 12944-1 indicates the following range:

- Low (L) from 2 to 5 years

- Medium (M) from 5 to 15 years

- High (H) over 15 years

Use the following reference to select your coating system in the durable way you require. The higher the resistance, the longer the time to the first maintenance, the greater the maintenance.

In this part I would like to limit on a point that is seen in many of the projects that are carried out lately, and that is to interpret the durability time of a coating system with "warranty time", which are two totally different things.

The term durability is a technical consideration that can help the structure owner establish a maintenance program. On the other hand, a guarantee time is a consideration that is the legal issue of the clauses in the administrative part of the contract.

"The warranty time is usually less than the durability time, and there are no rules linking the two time periods."

Design considerations

Before defining the method of surface preparation of the structure to be used during the course of the project, the design of the structure must first be examined and be sure that the places susceptible to corrosion have been avoided as little as possible and that adequate access is available for coating application work, we have to remember that a good structural design can control corrosion by removing one or more of the components that could generate it, such as:

- Contact of dissimilar metals.

- Incompatible environments.

- Water traps.

- Slots.

- Limited access to the work area.

Photo 3: The design of the structure must be examined and be sure that the places susceptible to corrosion have been avoided as little as possible and that adequate access is available for coating application work.

Types and preparation of surfaces

Once the first three steps were developed, we can now continue with defining or identifying the different types of materials that will be used during the course of the project, it should be remembered that the selection of construction materials are made according to their physical and mechanical properties (temperature resistance, toughness to low temperature, resistance to thermal shock, etc.) and also to its properties of chemical resistance or resistance to corrosion by the medium it faces.

The most used material is mostly steel, but from there we have other alternatives of materials such as galvanized, aluminum and its alloys, titanium, stainless steels, etc. Each of which may have the same or different method of surface preparation.

Photo 4: Identify the different types of materials to be used during the course of the project.

In these cases, it is advisable to consult the coating supplier with which knowledge can be supported on what types of coatings can be compatible with each of the construction materials that will be used in the project.

Coating system selection

Carrying out this stage of selection of the coating system for the project, involves greater attention because this stage involves a correct relationship with the other previous steps (the environment, service conditions, estimated duration time, surface preparation, etc.)

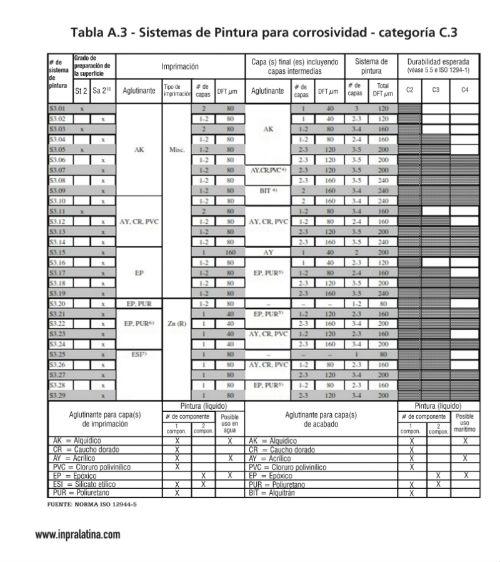

Initially we have to identify the different types of alternatives of coating systems with the required durability according to our given expectations, for this part we can be very useful the ISO 12944-5 standard that presents us with a different tables with different types of systems and for each type of environment, an example is like the one shown in table A3.

Now, as can be seen in the table mentioned, we can have more than 10 alternatives of coating systems that can be incorporated into the project specification, so our second objective is to try to reduce this number to about 2 or 3 alternatives that can be considered in our document. To do this, the following considerations must be taken:

- Select cost-based systems.

- Select based on the availability of the product in the local market.

- Select based on the analysis of a set of factors that can affect your behavior or coating life.

As for the coating we can consider:

- Basic functions that the coating must fulfill.

- Standardization of technical information.

- Advantages and disadvantages of coatings, as well as their limitations

- Performance and durability characteristics.

It is worth mentioning that in this last part you can also consider the respective advice of the coating suppliers based on their knowledge of their products or ultimately you can resort to external consultants specialized in the subject, in order to be impartial when developing the technical specification and there is no preference for a particular brand.

Photo 5: The stage of selecting the coating system for the project involves greater attention because this stage involves a correct relationship with the other previous steps (the environment, service conditions, estimated duration time, surface preparation, etc.)

As we had mentioned at the beginning of the article, there are other documents with which information support can be given, for the development of this article the ISO 12944 standard was taken as a reference, but there are others such as the SSPC, which show us a broader classification of environments, 12 classes and that later also presents recommended painting systems for each of its types of environments offering us a greater range of alternatives.

Whatever information we rely on, the important thing is in the end to obtain a technical specification that provides us:

• Confidence that the corrosion protection you specify will be fit for purpose

• An objective approach to coating selection

• A simplified matrix of coating systems to select from

• A significant coating design life

• A universally accepted standard

Remember, when selecting the most cost-effective system for your project, durability does not equate to a warranty time. Durability refers to the performance duration of the coating system before the first major maintenance. Minor maintenance should always be anticipated in order to achieve the necessary life until the first major maintenance.

Table 1: Source: ISO 12944-2

Table 2. Source: ISO 12944-5

* Eng. Nicolás F. Oriundo De la Cruz, General Manager OF SCC Ingenieros y Consultores S.A.C of Peru. NACE Inspector Level 2 CIP N° 39046. You can contact him by email [email protected] or by phone: +511 9878 16879.

Leave your comment