The Asian giant has many things to offer the world of coatings. How much have the Chinese exceeded in the production of raw materials?

Asian giant has many things to offer the world of coatings. How much have the Chinese exceeded in the production of raw materials?

by José Tomás Rojas*

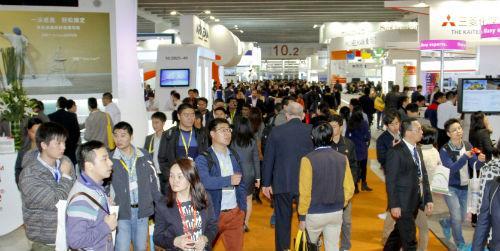

In 2011 I had the opportunity to attend the international painting fair known as CHINACOAT, which that year was held in the City of Shanghai. At that particular time, the purpose of many of those attending the event was to gain access to low-cost raw materials, in particular Titanium Dioxide, but also other materials such as resins and colored pigments.

Titanium, however, was the vedette of the event and rightly so; its use in paints is fundamental, representing a market that moves figures of the order of 5 million tons per year, at a cost of about US $ 12,000 million. This, of course, has a tremendous impact on the cost structure of paint formulations, so getting advantages with this product can have definitive effects on the economic results of a paint company, even more so considering that at the time, the supply of the product from China could be in price orders with differentials up to US $ 1 per Kg, against traditional titaniums.

This enormous opportunity, however, faced a basic questioning; quality assessments of Chinese products revealed significant differences in industry-critical parameters such as dispersion time, coating and whiteness, ultimately resulting in material cost savings being lost due to lower productivity and increased costs due to increased use in the formulas.

Despite this, many manufacturers managed to incorporate the material into their products, alone or combined with traditional titaniums, with a positive balance in profitability. Now, it is worth noting that, regardless of whether the quality of the product did not compete with international standards, China had managed to develop the Titanium Dioxide manufacturing industry, a company that is definitely not easy, due to the difficulty involved in handling large quantities of corrosive substances, indispensable for its manufacture.

The manufacturing "Know How", and this was told to me in one of my visits to the titanium manufacturers area of the fair, came from the recruitment of qualified technicians, often former workers of companies with a great tradition in the market. At the end of the event, the generalized criterion placed Chinese products as derivatives of the imitation of technology, cheap and of dubious quality.

I returned to Shanghai at the end of last year, attending the Chinacoat again, and as usual titanium was the protagonist, but this time, I observed very important changes. The price gap had narrowed quite a bit, a sign that the product was competing in performance with its traditional rivals. There have been significant increases in production capacity, development of titanium varieties for architectural and industrial areas and product quality, highly concentrated in about five manufacturers that have already acquired worldwide renown and participation.

Additionally, titaniums developed under the Chloride process were being presented, which implies a material with better whiteness and covering, made with a production process with less environmental impact, which implies an Engineering project with a very important investment of resources. On the previous occasion it was relatively easy to be attended by the commercial staff, this time however, it was necessary to make waiting shifts, due to the enormous attendance of interested in the products.

It must be said that there are still questions regarding the ease of dispersion, however, Chinese products have been favored by the emergence of new dispersion technologies in process, which have allowed the incorporation of the material into formulations, particularly in the case of industrial products. For processes that use high-speed dispersion, traditional titaniums are still preferred. My view is that while Chinese producers already dominate the manufacturing process, they still have limitations with the surface treatment of titanium particles, technology that is the domain of reputable manufacturers such as Kronos and DuPont (now Chemours). Now, I don't think it will take long for us to have Chinese titaniums suitable for high-speed dispersion.

The improvements I mention have occurred in the relatively short space, of 4 years. There has been no innovation as such, but imitations are now much more competitive, and this does not only apply to titanium; Similar improvements are observed in other materials such as emulsions, resins, pigments and additives. Part of this progress is due to the investment that the Chinese government is making in research and development projects, and the emergence of industrial technology seedbeds, through the union of universities and producers, who have done a very important job in the development of technology of products, processes and machinery for the paint industry.

What's next for China?

Will China continue on the path of imitation, or will it make the leap to innovation? I don't really know. Imitation (without this sounding pejorative, since imitating well requires a good dose of knowledge and technology), has given them good results. It seems that a culture of imitation has been established there, which still has for several years, and that will last as long as the price difference remains attractive to users.

* José Tomás Rojas. JTROJAS Pinturas, F.P. You can send your comments to the email [email protected]

Leave your comment