The evaluation of two geographical areas was carried out for the selection and estimation of the atmospheric corrosivity category based on ISO 9223 through a methodology that includes the measurement of the percentage of relative humidity (% RH), the measurement of temperature (T) and the deposition of chlorides (Sd) with the considerations for each type of measurement and registration.

By Pedro Moreno Junco*

In the development of new construction and maintenance projects, the category of atmospheric corrosivity is often established through subjective criteria, which are based on the collection of visual data without taking into account the industrial situation surrounding the operations that are being carried out without any analysis.

The complex factor of evaluation and the corresponding tests are still left aside, since these carry an investment translated into costs, time, technique and analysis.

Assigning the category of atmospheric corrosion without prior knowledge and analysis of the standards leads to an unnecessary increase in the cost of corrosion testing of coating systems in salt spray chambers, immersion cycles, UV exposure, etc.; guarantees required of contractors without technical criteria and overestimated or very light durability for projects in progress.

ISO 9223 defines two concepts that allow the selection of an atmospheric corrosivity category to be best addressed: "Determination of corrosivity" and "Estimation of corrosivity". Both concepts encompass different approaches to the selection of categories and at the same time allow to elucidate a scientific approach that sets in motion a better selection and obtain more real data that often the specifiers and corrosion engineers do not reflect in the standards for different companies.

Based on the above, this article presents a practical guide, without the purpose of replacing any standard or laboratory technique, that allows "Estimating the category of atmospheric corrosivity" through inspection, measurements, calculations and records to direct a scientific analysis and a shorter route when selecting the Category of Atmospheric Corrosivity with quantitative values and extrapolable from the regulations.

During the description of each stage it is understood that the level of uncertainty in a process like this is high, so it is clear that during the execution of each inspection and evaluation of calculations in the cases exposed it is only being considered that the results express the time in which each function variable was taken, which are: the percentage of relative humidity (% RH), temperature (T) and chloride deposition (Sd) and do not represent annual monitoring.

However, the experience and results of the cases described shorten the probability of error and the level of uncertainty, rather, are limited to what is dictated by the regulations.

Methodology for estimating atmospheric corrosivity

When it is not possible to "determine" and select an atmospheric corrosivity category under the standard specimen control criteria and material loss based data to determine the corrosion rate, at least in an evaluation period of one year, a route can be followed based on the minimum analyses that must be completed in the field.

They are normative and bibliographic analyses to "estimate" the Atmospheric Corrosivity and to be able to predict the corrosion attack in situ and the corrosion attack in a longer exposure time.

The steps described below do not necessarily have to follow the prescribed order. However, from the experience of the execution of these, the order indicated in Graph No1 is recommended:

Graph No 1: Diagram of steps for the Estimation of the Atmospheric Corrosivity Category

Step No 1: Evaluation of the percentage of relative humidity in a given period

To record the percentage of relative humidity is to know the wetting to which a local atmospheric zone is exposed. Wetting is one of the functional factors responsible for the increase in corrosion rates, and, therefore, the accumulation of corrosive agents.

It is clear that its measurement in the field, using the most current devices, is simple and quick to record. Therefore, it is essential that when performing this operation three important aspects are chosen:

Areas with higher risk of moisture accumulation

Areas with lower moisture accumulation rate

Define an evaluation time

The first two aspects are subject to the inspection and configuration of the space in which the percentage of Relative Humidity is measured. It is necessary to consider internal atmospheres with a stable microclimate and outdoor atmospheres (marine and chemical) that have longer wetting cycles and are affected by the deposition of pollutants.

However, defining a time is perhaps the critical point when trying to make a successful evaluation in data collection. It is clear that the more time is taken, it is possible to have a better picture of the variation of %RH, considering the most extreme points of the measurement and obtaining a statistical average with more information.

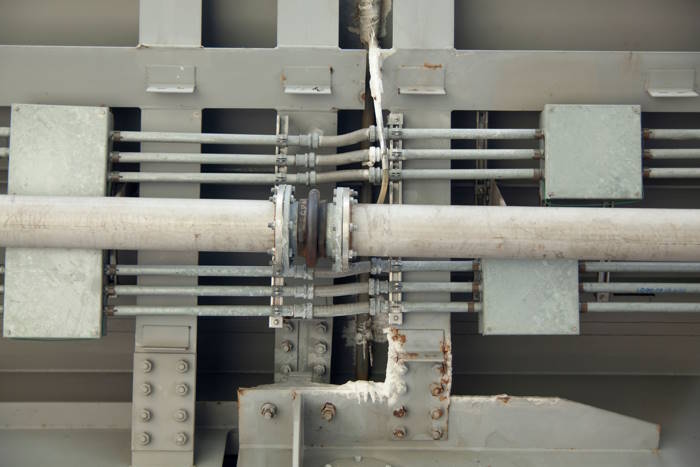

Step No 2: Extraction and measurement of salts

Salts, as well known, are hygroscopic agents. This property allows them to concentrate moisture, and therefore be a corrosive agent. In particular for structures and equipment present in different industrial environments, the accumulation of salts accelerates corrosion and degrades the coating and the steel itself.

This article will not detail the mechanisms, but its understanding as a corrosive agent allows us to elucidate which electrolyte itself should be evaluated when performing the inspection and sampling in the field.

In ISO 9223 and ISO 9224, the main corrosive agents to be evaluated in the field are chloride deposition (Cl−) expressed as Sd and sulfur dioxide (SO2) deposition, expressed as Pd. However, it should be mentioned that, according to the industrial environment, corrosive agents are diverse as indicated in table B.2 of ISO 9223. Among the main ones are NO2(g), H2S(g), NH3(g), Cl2(g) etc.

Establishing a baseline as indicated in the technical guide SSPC-Guide 24 helps to determine how is the behavior and accumulation of salts and contaminants in the various configurations of equipment and structural design.

The most common is to determine the amount of chlorides dissolved on the surface. For this it is recommended to use the Chlor*test kit.

It is clear that it is not intended to perform countless tests that the inspection time cannot cover and the costs associated with the inspection are increased, but you can consider the indications of the SSPC-Guide 24 that establishes the number of tests and locations according to the following points:

Complexity and structural configuration

Surfaces protected from contamination

Contaminated surfaces washed by rain

Areas of accumulation and trapping of moisture and contaminants

Areas that may be more prone to corrosion processes (depending on the temperature and process of the equipment)

These points provide guidance to establish a number of minimum evaluations in areas that will be most affected by the presence and accumulation of salts over time.

Corrosion Consultant*

General Manager / CEO

Cell: 983438940

www.iptperu.com

Leave your comment