There are many characteristics to take into account when formulating water-based architectural paintings. Below we present important aspects to develop an ideal product.

There are many characteristics to take into account when formulating water-based architectural paintings. Below we present important aspects to develop an ideal product.

by Manuel Chire Sarayasi, Oscar E. Chupayo Yauri*

An architectural painting formulation must align with chemical knowledge; although very rarely, in this type of formulations we use chemistry in a reactionary sense, that is, considering that the raw materials when mixed do not react with each other in an inconvenient way.

Another important aspect is observed during the application phase, where some of the raw materials undergo important physical and chemical transformations triggered by the modification of environmental conditions, so it is said that the functionalities of the formulated products are based on a reactivity of the raw materials.

Fig. N°1. The image shows the cracking of the film by the use of very high TMMF resins or the absence of coalescing agents in the formulation. A coalescing agent reduces the minimum film formation temperature (TMMF) and facilitates the coalescence of dispersion particles during film formation.

A good formulation develops high quality products, relying on the molecular knowledge and functionality of each input, so controlling the physicochemical characteristics throughout the production process is crucial for each raw material to have a good performance in the formulation.

When formulating an architectural painting, we must pay special attention to the characteristics and properties that we want to obtain, for example:

Water plays a very important role in the stabilization and performance of our paints, it must meet an indispensable requirement: contain the least amount of dissolved metal ions, since these interfere with the processes of wetting pigments and fillers, bases of concentrated pigments and efficiency of dispersants.

Alkalizers must be efficient at low concentrations, avoiding those that react and change the color of emulsions, especially low-cost vinyl.

Emulsions and coalescing: if we need the paint to perform well in cold environments we must use a resin with a very low TMMF (Minimum Temperature of Film Formation) or a very efficient coalescing that decreases it, or emulsions with values of Tg (Glass Transition Temperature) suitable that allow to formulate paints with elastic capacities.

Biocides must be selected according to the geographical area where the paint will be applied, parameters such as temperature, relative humidity, must be considered to ensure an adequate shelf life of the paint; if we look for attributes such as antibacterial paints, we will need broad-spectrum biocides that act on the dry film.

As for additives, the commercial offer in recent years and green trends lead us to identify additives with zero VOC content and odor, moisturizers free of ethoxylated alkylphenols, coalescing of vegetable origin and renewable sources, among other novelties.

Pigments also accompany these trends and we find pigments of high performance and durability, UV resistance and nanotechnology applied in titanium dioxide with catalytic properties.

Fig. N°2. Antibacterial paints are booming in countries due to their benefits to the consumer.

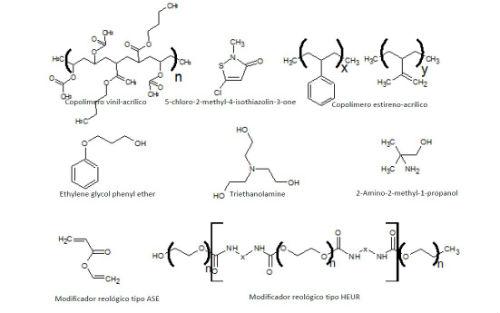

The chemistry of these inputs is very varied, ranging from simple molecules to complex linear and cross-linked polymers, assembled with various functional groups. Each of these structures are unique to meet certain functionality; therefore the insistence on knowing in detail the relationship between the chemical structure and the functionality of each input.

Fig. N°3. Molecular structures of some of the raw materials used in the elaboration of architectural paintings.

The raw materials we use require special conditions so that they can perform well; to control these conditions, the physicochemical analysis is present through instruments and analytical techniques that allow us to know these conditions during the process, and thanks to these results we can regulate the conditions to the requirements of each input.

The potentiometer is the most indispensable measuring instrument that allows us to control one of the most important conditions in a painting, the pH. pH values between 7.5 – 8.5, allow an adequate functionality of many of the inputs present in an architectural painting, such as the stabilization of the dispersed system, acceleration of the hydration process in cellulosic thickeners, thickening of HASE rheological modifiers, elimination of residual monomers of the binders and therefore of the odor, and good performance of biocides type CMIT / MIT.

Another suggestible instrument is the Zeta Potential Analyzer, which allows to improve formulation stability and shelf life, as well as reduce formulation time and costs; this through the measurement of the zeta potential existing in a colloidal system, such as an aqueous paint.

The zeta potential is a measure of the magnitude of the repulsion or electrostatic (or charge) attraction between the particles, and is one of the fundamental parameters known to affect the stability of the system. Its measurement provides detailed information on the causes of dispersion, aggregation or flocculation, and can be applied to improve the formulation of dispersions, emulsions and suspensions.

Fig. N°4. The image shows part of the instrumentation required to verify the production process of architectural paintings.

At the end of a formula, we also need to characterize it through physicochemical techniques, in order to meet the requirements of standards present in the market. Various technical standards, present in our countries, such as the NTE standards (Ecuadorian Technical Standard), NTC (Colombian Technical Standard), NTP (Peruvian Technical Standard), among others; establish the requirements to be met by water-based paints used to coat exterior and interior surfaces.

To meet these requirements, instruments are needed that allow us to measure, quantify and classify the final properties of a product. Instruments such as the viscometer, pycnometer, stove, analytical balance, scrubbing machine, grindometer, film stretcher, etc. allow us to control certain characteristics in a final paint, such as viscosity, density, accelerated stability, resistance to high temperatures, percentage of solids, drying time, covering power, accelerated weathering tests, abrasion resistance, among others.

All these characteristics will be the ones that we have to assess when carrying out a project, to formulate a good water-based architectural painting.

* (1) Eng. Manuel Chire. Technical Marketing Specialist in Paints & Construction. Disan Perú S.A. You can send your comments to the email [email protected]

* (2) Chim. Oscar E. Chupayo. Technical Marketing Assistant. Disan Perú S.A. You can send your comments to the email [email protected]

Leave your comment