The demands of modern construction demand products for the filling of joints that resist the environmental conditions to which they will be exposed and that do not present cracks that put the surface at risk.

The demands of modern construction demand products for the filling of joints that resist the environmental conditions to which they will be exposed and that do not present cracks that put the surface at risk.

by Technical Department Diransa San Luis

In the construction or repair of homes, the need for the use of putties usually arises, both for the treatment of cracks and for the filling of expansion joints.

In cases of cracking it is important to identify the type of failure to select a treatment that provides a lasting repair. Thus, in a wall with plaster we can distinguish according to its origin and nature, three types of cracks and their respective methods of treatment:

- Type 1, cracks of 0.1 to 0.3mm wide only present on the surface of the plaster: these are fissures formed only in the last millimeters of the plaster due to a very fast drying of the same and / or an excess of fine loads in the mixture and / or its aging. These fissures are manifested especially in old plasters, to lime.

In this type of fissures it is best to seal the surface previously with a product based on a polymeric hydrosol of good penetration and fixation. Then indoors it is repaired with a thin layer of enduido to finally paint. Outdoors, after the hydrosol, it can be applied enduido, or, if the cracks are very fine, it can be finished directly with two or three hands of a quality elastomeric paint that ensures a solids content greater than 52% and a PVC between 60 and 70.

- Type 2, visible cracks of 0.2 to 0.8mm wide whose shapes coincide with those of the bricks or blocks of the wall: these cracks completely cross the plaster reaching the mortar joint copying the shape of the blocks and / or bricks.

The largest cracks and those caused by wall expansion, widen to approximately 5mm wide and 5mm deep. Then the entire surface is sealed with a product based on a polymeric hydrosol. Finally, cracks not subjected to movements are repaired with enduido for interior or exterior as appropriate. The deepened parts are filled with a suitable elastomeric putty and then a polyester mesh is glued over the crack in a floating manner. Finally, we proceed to apply the enduido and the finishing paint.

- Type 3: Important cracks of 0.5 to 10mm due to the construction technique: these are cracks that appear in the weak areas of buildings, for example in the meeting points between a wall and the ceiling or around windows and doors. They are produced by failures in the structure of the construction: movement of foundations, vibrations, joints of materials with different thermal expansion and / or humidity, etc.

The advisable thing in the case of masonry, is to remove about 5mm of plaster on each side of the path of the cracks. The surface is fixed with a hydrosol and the cavities are filled with a suitable elastic putty. A polyester mesh is glued in a floating way and then a thin layer of enduido is given so that the thickness of the putty plus that of the mesh with the enduido level with the surface of the wall, thus leaving the invisible crack at the time of giving the finishing paint.

Brick walls also experience failures due to thermal expansion and contraction or humidity. In these cases, the repair of the cracks is done by removing one to two centimeters deep from the material of the joints and then, if you have a static fissure, the joints are made up with cementitious mixture. If the fissure is exposed to dilations, the joints are filled with a suitable elastic putty, filling in a decorative way as can be seen in the photograph:

This elastic putty is also suitable in window or door frame joints, in floor and ceiling expansion joints, in elastic fillings for dry construction panels and in joints in the placement of ceramics for coating bathrooms and kitchens, etc.

When polymer makes a difference

Generally, the surfaces to be treated retain moisture and this makes it difficult to adhere to filling masses made with polyurethane compounds, silicones, rubbers and other solvent-based products (generally the manufacturers of these products clearly recommend using them on dry substrates). On the other hand, solvent-based compounds are difficult to paint with water-based coatings.

For these reasons and in favor of eliminating solvent emissions to the environment, it is essential to address the formulation of putties based on elastomeric polymers in aqueous dispersion of special characteristics.

Trying to meet the market demand, after extensive development work, an elastomeric acrylic polymer has been developed in aqueous emulsion specially designed for the formulation of masses for elastic filler joints.

The outstanding properties of this polymer allows the formulation of new generation putties with:

-High binder content.

-Exceptional adhesion.

-Permanent elasticity even at low temperatures.

-Low water absorption and good vapor permeability.

-Single component.

-Low VOC.

-Repaintables.

-Excellent stability in packaging.

To verify the properties described, a putty is made in the laboratory according to the following indicative formulation:

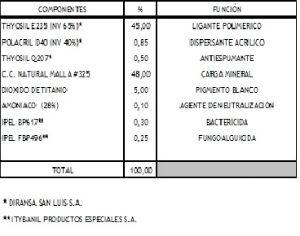

Dough for elastic filling joints

Specific Weight = 1.56 g/ml PH value = 8.00

Non-Volatile = 83.03 % Viscosity = 320000 cps

This paste was made by dispersion in a simple way, first mixing the emulsion with the dispersant and the antifoamer, then the pigment and carbonate were added and dispersed until the absence of agglomerates. Maintaining the agitation, the biocides were added and, finally, the pH was adjusted to 8.00 with ammonia.

Mechanical stability

In the manufacturing process, the dough was subjected to intense agitation of high cutting effort for 30 minutes, acquiring the paste temperatures above 40°C. This circumstance reveals a first fundamental question: "the polymer offers a great mechanical stability" that allows safe processes, free of excessive increases in viscosity or even coagulations with loss of the final properties of the product.

Thermal stability

The evolution of the viscosity of putty at room temperature, in a stove at 45°C for 30 days, was studied. The final results indicated viscosity increases of less than 3% for the sample at room temperature and increases of 5% for the 45°C sample. No fluid separations or clots were observed. The formulation remains stable, retaining its application characteristics.

Stability in sunlight (yellowing)

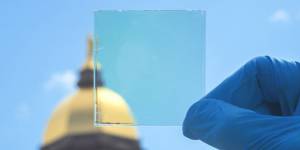

To see the effect of solar radiation, two formulated putties were applied on a glass plate, one based on a "polymer A" available on the market and the other based on the elastomeric acrylic polymer in aqueous emulsion, in order to choose the one with the best behavior. The exposure was carried out under glass for 30 days, after which the putty containing the "polymer A" revealed a high degree of yellowing, while the putty formulated with this polymer presented practically no increase in color.

Water absorption

This test was carried out by immersing specimens of putty of 25cm2 and 3mm thickness previously dried at room temperature for 15 days, in distilled water for 24 Hs. The following values were recorded:

Blistering test

To carry out this test, all the faces of a ceramic tile except one were sealed with an aqueous varnish to limit the migration of moisture. On the unsealed face of the tile, an application of putty with a metal spatula was made, forming a thickness of approximately one to two millimeters.

It was left to dry for two hours at room temperature and then placed on a stove at 45°C for 48 Hs. At the end of this time the application made did not present blistering.

Accession and elongation

The elongation curves (initial and aged) of the formulation were determined. Specimens of 3mm thickness were made dried seven days at room temperature. They were also aged at 45°C on the stove for three days.

While there is a loss of elongation to rupture due to thermal aging of approximately 20%, the putty will maintain in service a very good elongation of 400%. On the other hand, in tests carried out at 3°C, the elongation at rupture drops to approximately 300%, this being a more than acceptable value in usual use.

On the other hand, a test of filling joints of 2cm wide by 1cm thick between ceramic tiles that were fixed on a film was carried out. After a week of drying at room temperature, the temperature was raised to 45 ° C, maintaining the test in the stove for 48 Hs.Se observed that the putty applied contracted very little, that is, it showed very good filling power and did not present quarters or sectors with adhesion failures.

As can be seen in the photo, the joint mass between tiles was subjected to an angular stretch so that a 100% elongation was achieved without breakage on the one hand, and on the other, the adhesion on the ceramic substrate was exceptional.

In general in good construction practice, it is considered that a well-calculated joint should have a width of two to four times greater than the total expansion. Thus, for example, if a total movement of 5mm is anticipated, a joint width of 20mm should be chosen. If it is a crack, it will widen longitudinally and in depth.

In this way, the angular stretch observed in the photo at 100% elongation is a test that exceeds the exposed rules to establish a safety limit. In those cases where widening cannot be carried out and the joint experiences expansions greater than 100%, a filling whose elasticity is twice the required movement should be used.

Leave your comment