A deep analysis of both alternatives that will allow us to have a much broader picture of their characteristics, applications and the future that awaits them.

A deep analysis of both alternatives that will allow us to have a much broader picture of their characteristics, applications and the future that awaits them.

by José Tomás Rojas. Master in Paint Technology*

I would like to start this article by stating that no paint for architectural or industrial use is soluble in water. They can't be. If so, a water-based paint, for outdoor use, would only remain on the façade, until the occurrence of the first rain. It would work relatively well in Lima, where it hardly ever rains, but it would fail catastrophically in Venezuela, where the rains are very heavy. Being soluble, the paint film would be dragged from the surface, leaving the façade bare and rendering the paint job useless.

I allow myself this introduction to make it well established that the concept of water-based paint refers to a paint that is not soluble in water, but that can be reduced with water, that is, its viscosity can be decreased with the use of this universal solvent. This reduction is achieved by incorporating additives that are able to "compatibilize" substances of an incompatible nature such as the resins that make up the paint, and water.

Water-based architecture: use of surfactants

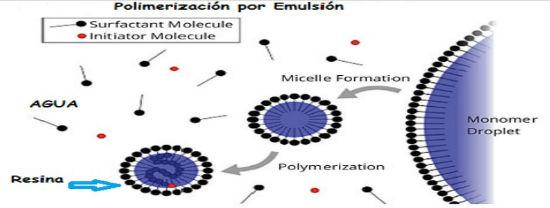

In the case of water-based paints, those of the architectural type in particular, whether these vinyls, latex or emulsified paints, compatibility is achieved mainly at the time of producing the base resin or latex, in a process known as Emulsion Polymerization. For this purpose, additives known as surfactants are introduced, whose chemical nature allows them to form a kind of bridge, one of whose ends is compatible with the monomer, or component that will give rise to the resin, and the other with water, which produces a stable aggregate known as Miscellaneous. Inside that Miscella, surrounded by water, the polymerization process occurs that will give rise to the resin. See Fig 1.

Figure 1. Emulsion polymerization. Note the drop of resin surrounded by water.

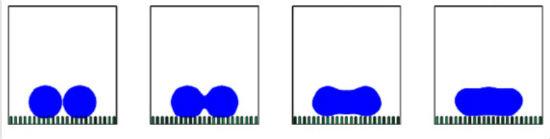

Thanks to this process we manage to obtain an insoluble polymer, encapsulated within the aqueous medium, which allows its stable diffusion in this medium. After application, the aqueous medium evaporates, releasing the insoluble polymer, responsible for forming the film, through a process known as Coalescence. What happens is that as the water evaporates, the distance between the micelles shortens, and finally they come into contact, giving rise to a continuous film. See Fig. 2.

Fig.2 Schematic representation of the Coalescence of micelles.

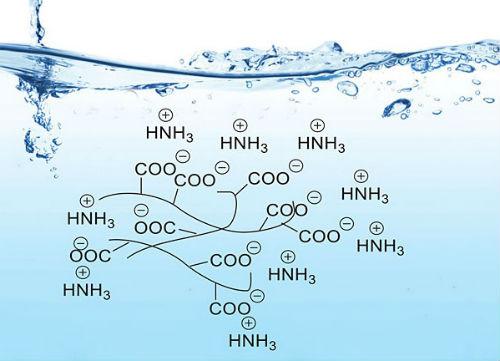

Water-based industrial paints: neutralization

Industrial paints are composed of resins that do not show any kind of compatibility with water. We speak in this case of alkyd resins, epoxy, polyester, acrylic, among others, and for these cases the use of surfactants as compatibilization agents is necessary, but not enough. To achieve water reduction, it is necessary to subject the resin to a chemical process known as neutralization. In the case of an alkyd resin, the presence of acid groups is used, which when treated with a soft base, can form compounds with sufficient polarity to make them related to water. See Fig. 3.

Fig. 3 Neutralization of acid groups in an alkyd resin.

Water-based or solvent-based?

In the past there was no doubt as to the type of paint that should be selected for this or that surface coating work. By then there was a well-defined classification in terms of the segments of use of water-based and solvent-based paints. The water-based, mainly the emulsified paints, were aimed at the architectural market, particularly interior and façade paintings. Solvent-based paints, including architectural enamels and industrial paints were aimed at the protection of metal structures. It is clear that the selection process was oriented by the type of surface to be coated. In the case of concrete or wood structures, the selection indicated water base. In the case of metals, the selection indicated solvent base.

There was a technical foundation behind such a selection. In the case of construction materials such as wood and concrete, already of good structural strength, the main objective, in addition to decoration, of course, was to protect the surface from deterioration caused by water and other elements present in the environment. In this case, an emulsified paint, hydrophobic in nature, could do the job efficiently and economically. A minimum mechanical resistance was required, by virtue of the fact that the structures would be subjected to little stress, separating the natural cycles of expansion and contraction product of the ambient temperature. Nor was a great adhesion required since, the porosity of the applied surfaces provided good anchor points to coating.

In the case of metal surfaces, the demands were much higher. Good corrosion protection, flexibility, mechanical strength, appearance and very good adhesion were required for the entire range of products of a metallic nature, among which we could mention cars, furniture, appliances, containers, tools, metal structures among others. None of this could be achieved with emulsified paints.

Environmental regulations

As a premise, we can say that the competition between water-based paints and solvent-based paints has only occurred in the field of protection of metal structures, and more than competition, we can speak more properly of a tendency to replace solvent-based paints with different alternatives, including water-based paints.

This trend has not been spontaneous, and has its origin in the appearance of regulations, mainly in the United States, which were aimed at requiring the reduction in the emission of volatile organic solvents into the environment, including Rule 66, the Clean Air Act, and an amendment to this Act, in 1977, which introduced the VOC (Volatile Organic Compound) concept, and regulated the obligatory nature of its reduction. Thanks to the requirements of these legislations, alternatives such as high solid paints, 100% solid paints, powder paints, and water-reducible paints have been developed, all of them aimed at reducing the content of organic solvents in their formulations.

Performance of water-based paints in metal coatings

The development of water-based coatings for metals has not been easy, and their performance cannot be qualified as optimal. The main obstacle that arises, in my opinion, is the low wetting capacity of the water, due to its high surface tension. This can be modified by incorporating surfactants, but the wetting that is achieved does not equal that obtained with solvent-based product. Having good wetting means better adhesion, and consequently better protection and better development of mechanical properties. Drying times, on the other hand, are usually longer in water-based paints, and this has a serious effect on productivity. Another aspect has to do with a phenomenon known as "Flash Rust", or instantaneous oxidation, which occurs when an active metal surface comes into contact with water. To avoid this, the formula should incorporate special antioxidant additives. Finally, the leveling obtained with water-based paints is usually poor, in relation to their solvent-based alternatives.

Speaking of my particular experience as a formulator, this type of paints are complicated to develop, require the incorporation of additives and special resins, demand many conditions from the user for their application, and in general are usually more expensive. That is why, despite already having the market with technologically feasible alternatives, its use has not spread, particularly in Latin America, where environmental regulations are not especially demanding.

In any case, the fundamental impulse to continue making improvements to these paintings lies in compliance with increasingly strict legislation. Now, it should be considered that although these paintings represent a decrease in the emission of VOCs, they also have risks for the environment. This is because, being reducible with water, this same element is used to clean the equipment used in its application, which implies that there are possibilities of sending to the waterways remains of the organic additives that have been used to develop the application properties. An example of this is achieved in emulsified paints, where the most widely used surfactant, Ethoxylated Nonyl Phenol, has been questioned for the impact it can have on aquatic life, which it manages to access, dissolved in the waters used for cleaning the equipment used in the manufacture and application.

In short, I believe that there is no real competition between water-based paints and solvent-based paints. Much work remains to be done and effectively functional technologies in terms of cost-performance are not yet available. On the other hand, other replacement options such as high solids paints, 100% Solids, and powder paints, have managed to achieve better results in terms of performance, being functional alternatives, very important in the progressive elimination of the use of solvent-based paints.

* Lic. José Tomas Rojas. MSc. President JTROJAS PINTURAS. Email: [email protected] Twitter: @JtrojasPinturas. Whatsapp: +584143498149