Presentation of high performance solutions for infrastructure waterproofing and Success Story in Latin America.

Presentation of high performance solutions for infrastructure waterproofing and Success Story in Latin America.

by Mauricio Torres and Omar Hernández*

The industrial and construction segments require increasingly efficient solutions that solve the problems of wear and tear suffered by the infrastructure in the different exposure environments. Some of the most common problems are:

1. Corrosion

2. Erosion

3. Leaks

4. Impact damage

5. Abrasion wear and structural movements

6. Chemical attacks

Multiple efforts have been made for the development of coatings that protect the value of these constructions by protecting them from the aforementioned aggressive means. Among the most commonly used solutions are alkylsilanes and siloxanes (hydrophybic), acrylates, epoxy systems, vinylesters reinforced with glass fiber, epoxy-polyamides, thermofused rubber and polyurethanes/polyureas.

Polyurea has been used since the late eighties mainly in North America to repair infrastructure in bridges, tunnels and residential roofs. In recent years Dow has invested in the development of new formulations recognized in the market seeking to improve their performance in increasingly aggressive environments, in compliance with the needs of the market. The advantages of polyurea and these latest developments are significant compared to conventional protection systems, among these the following stand out:

Accelerated reactivity derived from polyether amine kinetics with isocyanates, allowing a rapid return to post-application service

Can be applied on both horizontal and vertical surfaces without suffering dripping or surface deformation effects

During the application of polyurea there is a relative insensitivity to water and ambient temperature which allows a good performance in a wide range of working conditions.

It is a 100% solid coating, with two components, being environmentally friendly as it does not contain VOCs (Volatile Organic Compounds)

Thicknesses greater than 2 mm are easily achievable, which translates into superior durability and strength.

It exhibits superior physical properties compared to other polymers, qualities such as higher elongation, tension and abrasion

Shows very good thermal stability (- 30°C - 100°C)

It offers a wide window of products with different characteristics depending on the needs of each project (high and low hardness systems, systems with chemical resistance, systems with modified behaviors to the flame, etc.)

The polyureas during their reaction generate a monolithic, seamless coating.

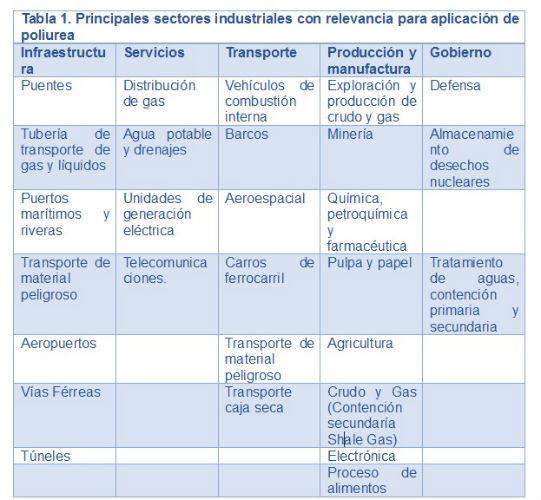

All these advantages translate for construction and engineering companies into benefits such as durability and productivity for different sectors of the industry. The main areas of application of polyurea are described in Table 1.

Table 1.

Success stories in the North Region of Latin America

The recognition of Dow's polyurea and primary brands known as Vorastar, Traffideck and Hyperlast has been built on the success of complex and challenging projects, some of these projects are summarized below:

1- Deep drainage of Mexico City: The concrete of this important infrastructure of the capital of Mexico presented a severe attack by corrosion by the hydrogen and sulfuric sulfide product of the anaerobic decomposition of the organic matter present in the environment, as well as abrasive attack by the solids contained in the water, which meant a risk of structural collapse. 35,000 m2 were protected in 2009 and 14,000 m2 in 2011 with the Traffideck MT moisture-tolerant epoxy primary system and the Vorastar chemical-resistant polyurea.

2- Baluarte Bridge: The metal structure of the voussoirs of the highest cable-stayed bridge in the world were protected from corrosion with Dow's solution, where 20,000 m2 were applied between 2010 and 2011 using epoxy primary with zinc loads and Vorastar polyureas.

3- Protection of the Quetzal port: The concrete of the dock of one of the most important ports in Central America was damaged by saline attack, water filtration and wave shock. To protect this important infrastructure, 7,000 m2 were coated with Vorastar polyurea using Traffideck MT moisture-tolerant epoxy primary.

4- Drainage of the Tula refinery: Replicating the case of the Mexico City deep drainage project, 30,000 m2 were protected in 2014, in areas composed of 3x3 m channels and 6 m diameter drains from the Tula refinery. The objective was to create a protective layer from the potential chemical and abrasive attack of the water of the petrochemical complex, this protection was given with the Epoxy primary system tolerant to the MT humidity and the chemical resistant polyurea brand.

5- Water treatment plant: Clarifier tanks, storage pools, storage tanks, transfer channels and cisterns of water treatment plants of both private and government industry have been protected, with the epoxy primary system tolerant to moisture and polyurea resistant to chemicals. The last success story occurred in 2016 in the water treatment plant of nuevo Pemex, where 6,000 m2 were covered with the aim of creating a layer resistant to chemical attack and abrasive medium, as well as water leaks through concrete.

6- Cancun / Cabo San Lucas water bodies: Vorastar and Hyperlast polyureas were applied in residential and hotel complexes of the Mayan Rivera and Cabo San Lucas with the aim of protecting the concrete structures of water bodies from chemical attack (by chlorinated compounds) and water leaks.

7- Duarte corridor tunnel: Polyurea was applied in the Duarte corridor tunnel project in the Dominican Republic in 2011, replacing the waterproof membranes (PVC) most commonly used for this application, showing polyureas their advantages in terms of rapid return to service and minimum personnel necessary for their installation. The result was productivity gains of just over double compared to labor-intensive PVC.

References:

- Bruchertseifer, C. Mueller, G. PU Spray Elastomers with Improved Resistance to Chemical Attack – Studies on properties and performance.

- Bruchertseifer, C. (2006). Polyurea spray application II – First objects reference on the way to a comprehensive case history. CRI number 2007000045

* Mauricio Torres, Specialist in Development and Technical Service in Polyurethanes of Dow. Omar Hernández, Technical Commercial Representative in Polyurethanes of Dow.

Leave your comment