In the first part the difference between pigment and dye was deeply explained, in addition an introduction was made about what inactive pigments are, a topic that continues in the closing of this interesting article.

In the first part the difference between pigment and dye was deeply explained, in addition an introduction was made about what inactive pigments are, a topic that continues in the closing of this interesting article.

by Julián Restrepo*

We have already talked a little about inactive pigments, but at this point we can say that inactive pigments are those that "have no optical activity" in the coating, since by definition they do not provide color and opacity, so they are insoluble in the vehicle, but that they have a much lower price than that of active pigments (such as that associated with titanium dioxide and other organic pigments, for example), and are mainly used to lower the cost of paints.

The general name used to designate the type of pigments that do not provide color is that of inactive pigments, inert pigments or simply fillers.

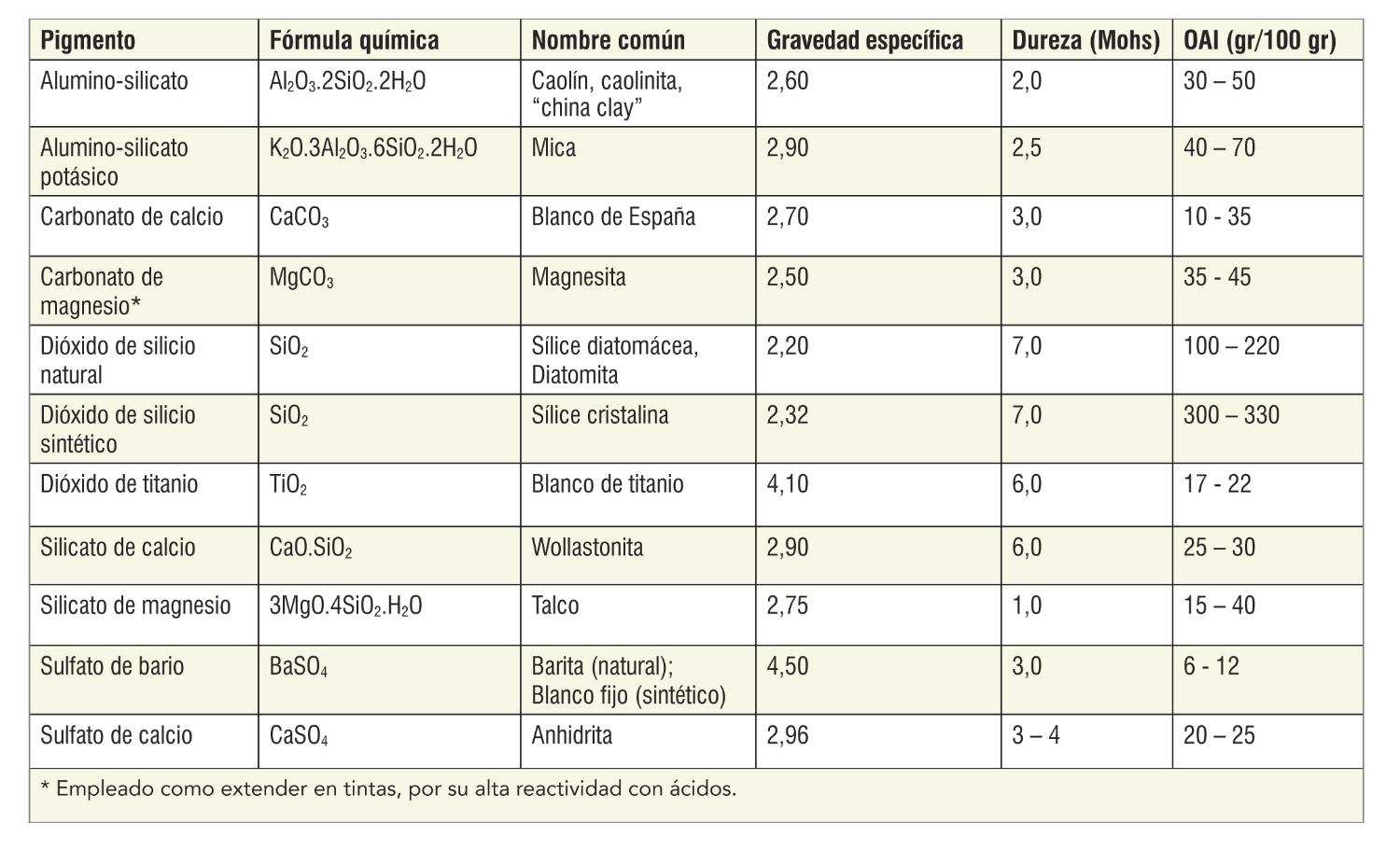

Below is the following table relating the most commonly used inactive pigments in the paint industry (active pigments such as titanium dioxide and barium sulfate have been included, for illustrative purposes) [2]:

But despite being simply called fillers, by careful selection of a specific type of inactive pigment for each particular type of coating, in some cases, certain properties of the coating can be improved.

That is, the proper selection of the inactive pigment at the formulation stage can improve different properties, such as viscosity, fluidity, rheology, permeability, hardness, washability and abrasion resistance; as well as conveniently favoring the sedimentation conditions in the container during the storage time, in order to avoid or reduce it to the maximum. Certain loads mechanically reinforce the structure of the dry film, while others increase its resistance and especially to the penetration of moisture through it.

In these cases where inactive pigments are not only limited to lowering the cost of paints, but also provide additional effects and properties, they are called "functional loads"; that is, its function is not limited to reducing the cost of painting, but to providing additional beneficial properties to it.

Such is the case of extenders, as a partial substitute for the active pigment. But there are other functional loads (in some cases considered as additives, according to the dose used), such as some rheological and anti-decanting agents (bentonites and hectorites) [3], matting agents (silicas), corrosion inhibitors (phosphates, hydroxyphosphites, phosphosilicates), among others; but the cost of these functional loads is, in many cases, higher than that of active pigments; that is, although they do not provide color, they provide other advantages that are highly appreciated by formulators and for which they are hardly surpassed by other materials.

Extenders

Among the inactive pigments are the extenders which, as already said above, are a type of functional loads.

Extender is an anglicism of the same word in English and that means extender and that denotes, among others, amplifier, enlarger or developer, and that contextualized to the formulation of coatings, indicates that the extenders, being loads, are not only used in order to reduce the cost of paints, because they are relatively cheap raw materials and their specific gravity is generally lower than that of an active pigment, but also, the extenders, due to their characteristics, are used to replace part of the active pigment in the formulation.

The best known types of extenders are titanium dioxide extenders (the white pigment par excellence used in the paint industry [4]), which is very important in the current context, considering the current situation that occurs with titanium dioxide, not only because of its variation in its international price, but because there are no new deposits and the demand is increasing, in addition to the fact that the costs associated with their production are increasingly higher, especially in the case of chloride grades.

Thus, as an inactive pigment such as an extender becomes important and becomes a valuable component to consider when reducing costs, since it allows to reduce a part of the titanium dioxide used, which is replaced by a pigment that is cheaper than titanium dioxide, maintaining the coverage and color, improving the availability of the materials to be used and also allowing to improve the balance of properties of the coating.

We can add that, the potentiation of the properties of an extender can be improved by using additives, as is the case of dispersing agents and humectants, which at a relatively low cost, will allow the extended employee to provide excellent performance [3].

There are cases where the use of an extender causes a favorable impact on other properties of the paint, such as the viscosity, rheology or pH of the product, which in turn allows to reduce the use of other raw materials, in many cases additives that are relatively expensive (pH regulators type AMP, thickeners, among other additives). That is, in this case we have that extending not only works as a "functional charge", since it not only allows "to extend part of the titanium dioxide", but interacts synergistically (1 + 1 = >2) with other components of the formulation; we could then talk about having a "functional extension", but it would already overload the term a little.

It should be noted that, due to the complex relationships that occur between the final properties of a coating and the raw materials used, it is expected that effects will be obtained in the different properties of the paint when replacing part of the active pigment. What happens, strictly speaking, is that the formulator always focuses his attention on a certain number of properties that "the end user will see", with which the others lose importance.

The inactive pigments usually used as extenders are found in pigments such as calcium carbonates, kaolins, talcs and silicas (note that they are of mineral origin). It is clear that the suppliers of these raw materials, by determining that their loads not only fulfill the function of lowering the cost of painting, but also provide other additional advantages (in this case, they work as extensions), raise the price of their product; which can be explained, in part, by the fact that these manufacturers subject their product to a greater number of purification operations, to provide it with greater added value.

Conclusions

It has therefore been seen that inactive pigments become key in the formulation of coatings, because their functions are not only limited to the fact of functioning as "transparent raw materials" and as a factor reducing the cost of paints, but in many cases, in reality, most, additional benefits can be obtained, they can even interact synergetically with other components of the formulation. Although, it should be borne in mind that although unwanted effects and antagonistic interactions can also occur, these are smaller compared to the benefits obtained.

The selection of the type of inactive pigment along with the appropriate additives is a factor that must be taken very seriously from the paint formulation process to obtain the best possible results.

References

[2] Correa, G. and Orrego, J., "Minerals are metallic in the coatings industry." Inpralatina, Vol. 4, No. 4, August/September 1999, pp. 20-26.

[3] Visit, for example, the website of the company Elementis Specialties: www.elementis.com, which offers a wide range of additives for different applications.

[4] Restrepo, J.A., "Titanium Dioxide: Give Your Application the Ideal Pigment." Inpralatina, Vol. 10, No. 1, January/February 2005, pp. 22-23.

*M.Sc. Ph.D. Technical Marketing at Insucolor S.A.S. Medellín, Colombia. You can visit the www.insucolor.com website