There are different mechanisms to clean this kind of equipment. But it is important to follow the recommendations on corporate responsibility that comes with performing this practice correctly.

There are different mechanisms to clean this kind of equipment. But it is important to follow the recommendations on corporate responsibility that comes with performing this practice correctly.

by José Tomás Rojas*

A reader has made a query about equipment cleaning in the paint industry. I briefly answered your question, but the matter encourages me to delve a little deeper into it, since it seems to me that this is a topic of great interest to the sector, for all the consequences that may be involved in it.

The paint industry, (specifically we refer to emulsified paints), consumes large amounts of water, both in its incorporation into products as a raw material, as well as for the cleaning of process equipment, including tanks, pumps, pipes, nozzles, among others.

Depending on the number of colors produced in the factory, as well as the contrast between them, the frequency between washes can be high, and consequently, the volumes of cleaning water that are generated will also be high. This can be a problem as cleaning water cannot be discharged directly into the drainage channels, because it contains significant proportions of pigments, latex resin and additives that can cause contamination of the waterways. In this sense, environmental legislation requires that these waters be previously subjected to a treatment that allows their safe incorporation into water channels.

Treatment plants

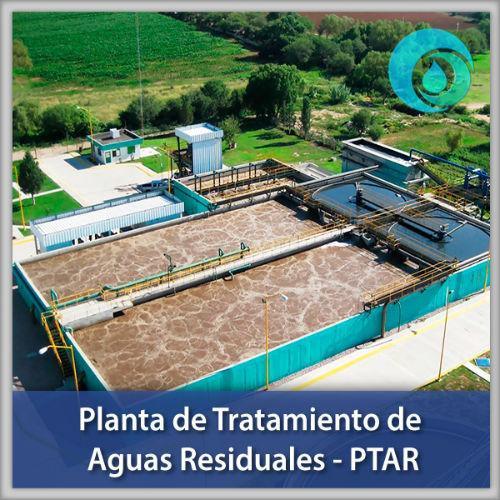

As the name implies, treatment plants are infrastructures that allow the conditioning of water from paint manufacturing processes, so that they can be safely discharged into drainage systems. The design and management of water treatment plants in the paint industry has its complexities, and must be handled by highly trained personnel. Its principle of operation is based on the use of a culture of biodigester bacteria, specific for the components of the paint, which can degrade the solids contained in the waters used by the process (also known as sludge), to take them to simple compounds, harmless to water bodies. Figure. 1.

Fig 1. Water treatment plant.

Of course, this is a process that requires many controls, since the quality of the treated water must be verified, before ordering its return to the environment. Additionally, the culture of bacteria is delicate, and its vital balance requires careful monitoring, otherwise its efficiency can be quickly lost. It is also necessary to take into account the type of waste that reaches the plant since, for example, adding a residue rich in biocides, could end the bacterial culture, severely affecting the cleaning process. These plants are frequently audited by government agencies to ensure that the treatment process works optimally, and failure to comply with established standards can result in significant penalties.

Effluent control

However, to ensure that the treatment plant is functioning properly, the volumes of water/sludge that are transferred to it must be regulated, and this makes one of the golden rules in the industry is that of minimization in the use of cleaning water. This is of utmost importance as it prevents overwork on the treatment process, because otherwise its efficiency is impaired, causing an increase in environmental risk.

There are several ways to minimize the use of cleaning water, the simplest, but sometimes the most difficult to implement, being the awareness of operators regarding the prudent use of this natural resource. This is why it is very important to train new workers (and also old ones), in terms of the water use cycle in the process, and more importantly, to highlight the consequences of indiscriminate water generation on the efficiency of the treatment plant.

Another procedure that helps a lot in the purpose of rationalizing the use of water is the efficient planning of color production. This is a strategy that involves first manufacturing the light colors, starting with the whites, then the pastel colors, until you reach the darkest shades. With this we avoid cleaning between color changes, since, normally, light tones are part of the darker tones, which avoids the risk of contamination, which does not happen in the opposite direction. Figure 2.

Fig. 2. Suggestion of a color gradient. For illustrative purposes only

Of course, the planning of color manufacturing must be done with the support of formulators, and process engineers, to determine the production order that best suits the needs of the process and business.

Pressure water cleaning

In any case, eventually it will be necessary to reach the cleaning, at the end of the cycle of dark colors, to return to the manufacture of light colors. In this case, it is advisable to use pressurized water systems, type Hidrojet, which allow an efficient cleaning of the equipment, while controlling the flow of water used very well. Figure 3.

Fig. 3. Hidrojet equipment for cleaning in the process.

Finally, we have the possibility of giving a use to the water / cleaning sludge, to avoid sending them to the treatment plant. The idea is to characterize this residue, determining solids content, bacteriological quality, color, pH and other properties, to use it again in the manufacture of dark colors, or formulate low-cost paints. There are units within factories that are dedicated exclusively to these recovery processes, quite successfully.

Note: I wrote these lines from the facilities of the new headquarters of the National Library of Peru, located in San Borja, Lima. Tweeter: @BibliotecaPeru. This is a beautiful building inaugurated in 2006, with extraordinary facilities and services for users. I want to thank them for the opportunity they gave me by becoming a member of such a distinguished Institution.

* Lic. José Tomas Rojas. MSc. President JTROJAS PINTURAS. Email: [email protected] Twitter: @JtrojasPinturas

Leave your comment