Cleaning and control of the washing of the material prior to hot dip galvanizing (acids and alkalis).

Cleaning and control of the washing of the material prior to hot dip galvanizing (acids and alkalis).

By Emmanuel Ramírez*

Introduction: To achieve a coating that meets the requirements of national and international standards, it is important to consider the following factors:

1. Chemical composition of steel (surface: roughness, tension, etc.). [1]

2. Surface treatment prior to immersion in Zinc (Material Cleaning).

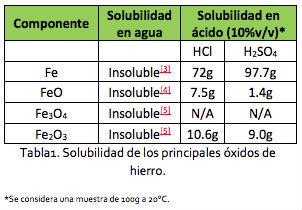

The main oxidation products of steel and most important by their proportion, are shown below: [2]

Table 1.

Due to the ionic character of the oxides, their solvation will be favored in acidic medium. It is important to consider the type of acid used and the concentration of it. In the case of magnetite, its solubility in acid will not be considered since its presence in almost negligible, in addition to its solubility in water is null according to the msds file. [5]

It is important to have a protocol that allows constant control of the parameters of acid and alkali baths (if applicable).

1. Degreasing

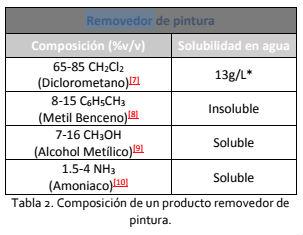

This step is crucial and most of the time necessary, since many times the parts to be galvanized are covered in considerable areas by various types of paints and greases. Below is the composition of a paint remover product and its components: [6]

Table 2.

Basic: the most common is the alkaline solution of NaOH. It is common to be found at temperatures between 50 and 70°C. The solution may contain Volatile Organic Compounds (VOCs) from previously applied chemicals (mainly paint removal).

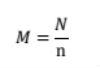

Concentration control [NaOH]: it is important to take into account that the reaction between HCl and NaOH is 1:1, and that the normal concentration or chemical equivalents per liter [N], may be considered as molar concentration [M]. As for the valuation of the Fe ion, work should be done in molar concentration, taking into account that: [11]

Figure 1.

Where: M= Molarity, N= Normality and n=number of electrons exchanged in the semireaction.

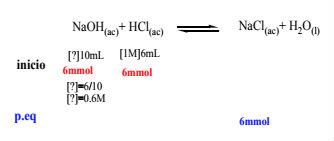

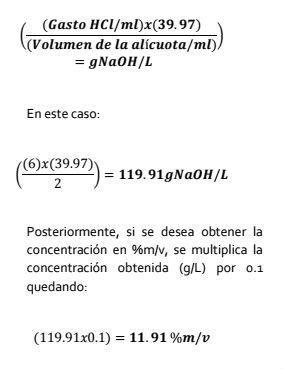

To calculate the concentration of the aliquot, the following parameters are taken into account:

1. Standard HCl concentration = [1N].

2. Expenditure of standard HCl = 6ml.

3. Total volume = 10ml.

4. Volume of the aliquot taken from the sample from the "soda degreasing" bath = 2ml.

5. Molecular mass of NaOH = 39.97g/mol.

6. Purity of "flake soda" = 98% (quality certificate according to supplier). [12]

The reaction proceeds as shown below:

Figure 2.

If you want to obtain the concentration in g/L, it is calculated using the following formula:

Figure 3.

In the event that the concentration is below or above the range of what is established by the plant procedures, the corresponding calculations must be made to keep it in optimal conditions.

Acid: HCl hydrochloric acid baths will be addressed to exemplify. Many times special products based on different acids are used such as: HCl, H2SO4 and HOCH2COOH. If the plant also operates with such special substances; it is advisable to contact the supplier to indicate the procedure to be followed for the optimal functioning of the product.

Note: The second part will deal with the topic of HCI Pickling, Flux iron concentration, and the conclusions of the article.

* Emmanuel Ramírez, head of the Technical Services Department of the AMEGAC (Mexican Association of Galvanizers). www.amegac.com

Leave your comment