Volume Pigment Concentration (PVC) and Critical PVC are important concepts in paint formulation.

Pigment Concentration (PVC) and Critical PVC are important concepts in paint formulation.

by José Tomás Rojas*

I worked at a company that had technology deals with "The Sherwin Williams Co." At that time we had a very picturesque General Manager, lover of baseball and boleros, extremely intelligent, but above all, of great human quality.

Our manager used to call the management team to his office to discuss the routine issues of a painting company, and for this he would gather us around on a round table, made of solid wood, built in oak. During our meetings, he never failed to mention, with great pride, that that table had belonged to Dr. Asbeck.

Now, who was Dr. Asbeck?

Dr. Asbeck was part of a high-level technical team that Sherwin Williams sent to Venezuela to deal with the technological issues associated with the formulation and manufacture of paints, while providing technical training to local staff. This exchange of knowledge was of great help in the training of Venezuelan professionals who would lead many segments of the national industry in the years to come.

Referencing the Asbeck lineage is very relevant in paint technology, as our Dr. Asbeck's brother, Dr. W.K Asbeck, alongside Dr.M. Van Loo, were the ones who, in 1949, defined critical PVC, one of the fundamental parameters in the formulation of Paints (1).

Critical PVC is a term that comes from a parameter known as PVC, (Pigment Volume Concentration) or Pigment Concentration in Volume, which measures the relationship between the total volume of pigments of the formulation, colored and filled, and the total volume of resin solids, according to the following expression:

PVC= (Pigment Volume / Pigment Volume + Resin Volume) x 100%.

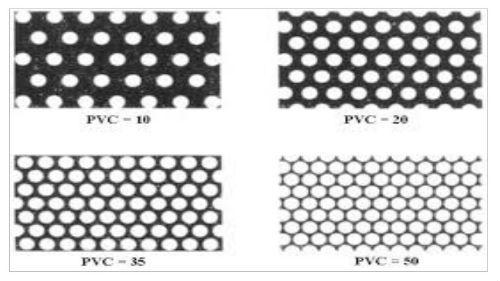

In Figure 1 you can see, in graphic form, what is the meaning of PVC:

Figure 1. Graphic detail of the increase in PVC.

The graph represents the ratio between a dispersed phase (pigments), and a continuous phase (resin). Some authors use at this point the term "Binder" or vehicle solids, which includes in addition to the resin, the additives that form the film. In our article we will use the term resin, the majority component, which allows us to better understand the concept we are handling.

A PVC of 10 indicates a product with a lot of resin and little pigment. We know that resin has two functions in a paint formula; maintain the dispersion of pigments, and promote the mechanical properties of the film. A PVC 10 indicates a product with enough resin to form a good protective film, with high gloss. However, the coverage, directly related to the pigment content, is low, due to the low presence of this material in the whole.

A PVC of 50 indicates a situation with a significant volume of pigment, where almost all the resin is compromised in its dispersion. The resin phase is still continuous, but the availability of it in the film, for protection functions, decreases, however, we have a product of very good coverage.

If we continue to add pigment to the formula, say above PVC 50, what will happen is that there will no longer be enough resin to disperse the pigment, occurring a discontinuity in the film that affects its protective properties, since said discontinuity generates a porosity that, among other things, allows the entry of aggressive factors from the surrounding medium, which can alter durability, adhesion, shine and other important properties.

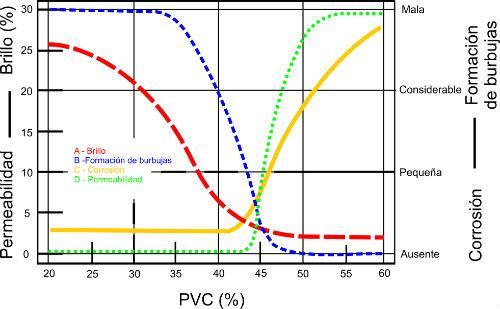

In Figure 2 we can see what happens to the properties of the paint, before an increase in PVC:

Figure 2. Variation of the properties of a paint, with PVC.

In low PVC situations, properties such as brightness (red), which depends exclusively on the resin, remains high. Meanwhile, the permeability (yellow) that depends on the continuity of the film, remains low. As PVC increases, the brightness decreases, because there is less resin available, but the permeability remains constant, because we still have a continuous phase.

There comes a point in the PVC where we notice a dramatic change in permeability, indicative that the continuity of the film has been broken. Properties such as adhesion and corrosion resistance are profoundly affected from this PVC. The PVC immediately prior to the occurrence of this situation, is what is known as the critical PVC or CPVC, and is defined as the PVC to which we have barely enough resin to have all the pigment content separated.

As a parameter, the CPVC is very important because it allows us to predict the behavior of a formulation, when we are formulating around this value, and alerts us to the profound affectation of properties that can occur when said value is exceeded.

Does all this mean that we cannot formulate paints above critical PVC? No. In fact we have many paints formulated well above critical PVC. This is the case of low-cost emulsified paints, with PVC greater than 85. In this case, the resin does not serve as a film former as such, acting rather as a binder of the pigment particles. As expected, according to the analysis we have been doing, the characteristics of these paintings are low brightness and poor washability, evidence of a discontinuous film. Premature chalking or heating are another characteristic of these paints, particularly those that are applied to the outside.

The concepts of PVC and CPVC are very important for the paint formulator, and should be considered, above all, when making changes to formulations. An increase or decrease in PVC, even when the weight ratios have been maintained, indicates that there has been a change in the specific gravity of some substitute pigment, which could significantly affect the volume ratios, and therefore, the performance of the final product.

For those who are wondering, I don't know what the final fate of Dr. Asbeck's table will have been.

* José Tomás Rojas. TROJAS Pinturas, F.P. You can send your comments to the email [email protected]

Reference

1.- W.K. Asbeck, M. Van Loo. Ind. Eng. Chem. 41 (1949). 1470

Leave your comment