High-performance natural calcium carbonates offer an optimal alternative to high-demand binder loads.

High-performance natural calcium carbonates offer an optimal alternative to high-demand binder loads.

By Adrià Galofré Martín*

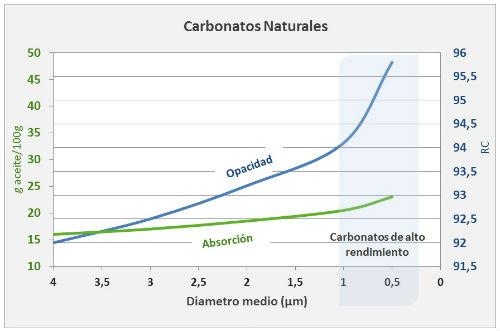

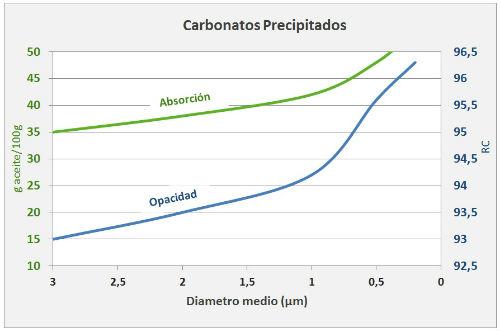

High-absorption mineral fillers, such as precipitated calcium carbonates (CCP) or calcined kaolins, offer good optical performance (e.g. opacity, gloss, etc.) at the cost of high binder demand. Ultra-micronized natural carbonates, on the other hand, provide a more favorable balance between performance and binder demand (see Figures 1 and 2). This relationship has a special impact when formulating near or above the Pigment Concentration in Critical Volume (CPVC), where a slight reduction in the amount of free resin will significantly reduce the resistance to rubbing and cause alterations in rheology.

Optimizing the cost-performance ratio

The most expensive ingredients of most decorative formulations, after additives, are titanium dioxide (TiO2) and resin. Thus, getting the most out of the first without wasting a gram of the second is a priority objective. In this line, Reverté Minerals has developed several ultra-micronized carbonates (d50 <0.8μm) of low oil absorption and a Particle Size Distribution (DTP) designed to maximize optical performance in paints of different CPV levels. The correct selection of these products, known as High Performance Natural Calcium Carbonates (CCNAR), allows to replace loads of high cost and high demand of binder, optimizing the relationship between optical, mechanical properties and the cost of the coating.

CCNAR – Two options for optimal performance

micral Opac Extra is a carbonate obtained from extra white marble. Its isodiametric DTP is designed to maximize the number of particles in the wavelength range of visible radiation. These characteristics make it a product especially suitable for highly loaded systems formulated above the critical CPV.

micral Tixtender is a newly developed product with a high number of particles below 0.5μm resulting in optimal packaging. This maximizes the dispersion and performance of TiO2 while maintaining an extraordinarily low binder demand. For this reason it is a product especially suitable for systems formulated near or below the CPVC.

CCP replacement – release resin without losing optical performance

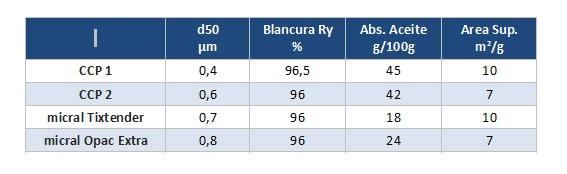

In order to establish the real possibilities of THE CCNAR as a competitive option, its performance has been evaluated against 2 commercial qualities of CPC. CCP 1 is a high-end product with a surface area of 10 m2/g. CCP 2 is a mid-range product with a surface area of 7 m2/g. Table 1 summarizes the main characteristics of the two SPCs evaluated together with the Reverté Minerals CCNAs used in this study.

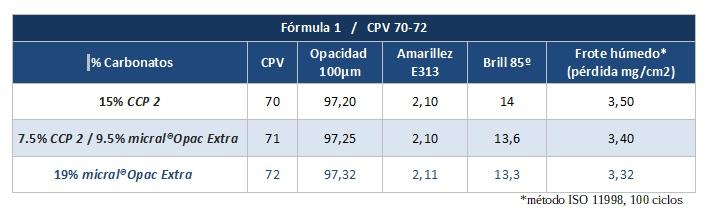

To replace CCP 1 in a CPV 30 system, micral Tixtender has been used. For the replacement of CCP 2 in a CPV 70 system, micral Opac Extra has been used. Figure 3 shows the two formulations used for the tests.

It is important to note that, in order to take advantage of the lower binder demand of CCNAs, CCP replacements have been made in a 1:1.25 ratio assuming a slight increase in the total CPV and the percentage of paint solids. While this could lead to expecting an impact on the mechanical properties of dry paint (especially in CPV>>CPVC formulations), the lower demand for binders of Natural Carbonates makes it foreseeable that it is possible to obtain stable mechanical resistance values.

Table 2 summarizes the results obtained by replacing CCP 2 with micral Opac Extra in formula 1 (CPV 70). A slight increase in opacity is observed along with a reduction in brightness to 85º. The variation in yellowness is not significant. The improvement obtained in the resistance to rubbing measured under conditions of the ISO 11998 method can be highlighted. This improvement is a direct consequence of the lower demand for binder of micral Opac Extra and the consequent increase in the amount of free resin in the dry film.

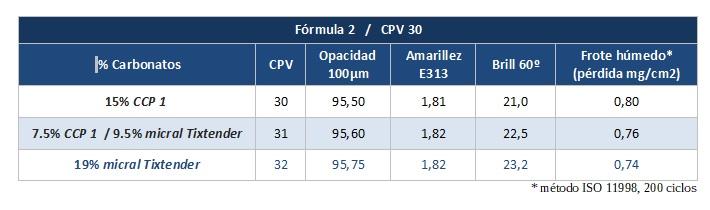

Table 3 shows the results obtained by replacing CCP 1 with micral Tixtender in formula 2 (CPV 30). In this case, there is a growing trend in opacity, a stable yellowness and a slight increase in brightness at 60º. The differences in wet rubbing resistance are not significant. Thus, it seems clear that small variations in the amount of free resin do not translate into effects on the mechanical properties in systems formulated below the critical CPV.

Conclusions

The use of CCNAR is a very competitive alternative to CCPs. The low demand for binder and the specific granulometric design of these allow to reformulate with increases in the CPV and the solids of the system, obtaining an optimal optical performance, a good mechanical resistance and a totally stable viscosity. In addition, the use of extra white marble as a raw material ensures a high whiteness and low yellowness, very close to the values of the CCP.

Taking into account the data presented and the cost of production of CCNAs, significantly lower than CCPs, the introduction of products such as those mentioned is a good example of how, by selecting suitable calcium carbonates, formulations can be optimized and attractive improvements in the performance/cost ratio can be obtained.

Finally, in a context in which ecology and sustainability are rising values, the carbon footprint of ingredients is of increasing importance. In this sense, the use of CCNAR as an alternative to CCP or Calcined Caolines is an attractive advantage and an increasingly important purchase argument for the final consumer.

* Adrià Galofré Martín. R+D+I – Technical Assistance of Reverté Minerals. You can contact him in his email: [email protected]

Leave your comment