United States. Purdue researchers have observed a way in which the brittle nature of ceramics can be overcome as they withstand heavy loads, leading to stronger structures, such as airplane engine blade linings and dental implants.

United States. Purdue researchers have observed a way in which the brittle nature of ceramics can be overcome as they withstand heavy loads, leading to stronger structures, such as airplane engine blade linings and dental implants.

While inherently strong, most ceramics tend to fracture suddenly when slightly tightened under a load, unless exposed to high temperatures. Ceramic structural components also require high temperatures to form first through a lengthy process called sintering, in which a powdered material is bonded into a solid mass.

These are problems for ceramic coatings of metal motor blades intended to protect metal cores from a range of operating temperatures. A study published in Nature Communications demonstrates for the first time that the application of an electric field to the formation of yttrium-stabilized zirconia (YSZ), a typical thermal barrier ceramic, makes the material almost as plastic or easily reformed as metal at room temperature.

Engineers could also see cracks sooner, as they begin to slowly form at a moderate temperature rather than higher temperatures, giving them time to rescue a structure.

"In the past, when we applied a high load at lower temperatures, a large amount of ceramic would fail catastrophically without warning," said Xinghang Zhang, a professor of materials engineering. "Now we can see the cracks coming, but the material remains attached; this is a predictable and much safer failure for the use of ceramics."

Recent studies have shown that the application of an electric field, or "flash", significantly accelerates the sintering process that forms YSZ and other ceramics, and at furnace temperatures much lower than conventional sintering. Evaporative sintered ceramics also have very little porosity, making them denser and therefore easier to deform. None have yet tested the ability of flash-sintered ceramics to change their shape at room temperature or increasingly higher temperatures.

"YSZ is a very typical thermal barrier coating, it basically protects a metal core from heat," said Haiyan Wang, Basil S. Turner professor of engineering at Purdue. "But it tends to suffer a lot of fractures when an engine heats up and cools down due to residual stresses."

What allows metals to be fracture-resistant and easy to change shape is the presence of "defects" or dislocations: extra planes of atoms that mix during deformation to cause a material to simply deform rather than break under a load.

Ceramics do not normally form dislocations unless they deform at very high temperatures. However, instant sintering introduces these dislocations and creates a smaller grain size in the resulting material.

"Smaller grains, such as nanocrystalline grains, can slip as the ceramic material deforms, helping it deform better," Wang said.

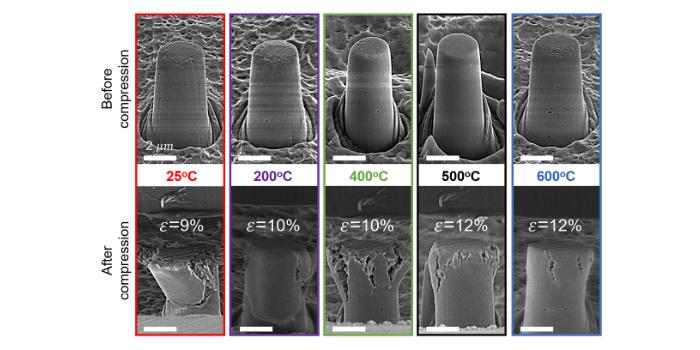

Pre-existing dislocations and small grain sizes allowed a sintered YSZ sample thinner than human hair to grow more plastically between room temperature and 600 degrees Celsius when compressed, with cracks slowly beginning to spread to 400 degrees compared to conventional sintered YSZ that requires 800 degrees and more to deform plastically.

Improved plastic means more stability during operation at relatively low temperatures. The sample could also withstand almost as much compression stress as some metals before cracks appear.

"Metals can be compressed with a stress of 10 or 20 percent, no problem, but ceramics often fracture into pieces if you compress them to less than 2-3 percent stress," Zhang said. "We show that flash-sintered ceramics can be compressed to 7-10 percent without catastrophic fracture."

Even when the sample began to crack, cracks formed very slowly and did not result in a complete collapse as would normally happen with conventional ceramics. The next steps would be to use these principles to design even stronger ceramic materials.

The researchers would not have been able to conduct in-situ experiments of a micrometer-sized ceramic sample without an in-situ nanomechanical test tool inside a high-resolution scanning electron microscope equipped with an iron beam focused tool at Purdue's Life Science Microscopy Center. an FEI Talos 200X electron microscope installation at Purdue's materials engineering facility. Both microscopes were provided by Purdue's Office of the Executive Vice President for Research and Partnerships and the Colleges of Engineering and Science. Purdue expects an even higher resolution aberration correction microscope that researchers will soon use for future nanomaterials research.

Data Source Provider: Purdue University.

Leave your comment