United States. Researchers at Ohio State University have invented a nano coating for synthetic leather that repels both water and oil, which cleans itself and won't become sticky on a hot day.

United States. Researchers at Ohio State University have invented a nano coating for synthetic leather that repels both water and oil, which cleans itself and won't become sticky on a hot day.

Researchers have previously used a nanodesign texture based on the fuzzy sheets to design self-cleaning glass and a mesh that separates oil from water.

Now they found a way to adapt the same nature-inspired coating to plastic-based synthetic leather. Both water and oil come out of the coating, preventing the leather-like surface from becoming sticky up to temperatures of 70 degrees Celsius (158 degrees Fahrenheit).

The siding could provide cleaner, less sticky furniture, car interiors, clothing, shoes and handbags— any product people use synthetic leather for, said Bharat Bhushan, Ohio Eminent Scholar and Howard D. Winbigler, a professor of mechanical engineering at Ohio State.

"Genuine leather has been an important material since the beginning of human history," Bhushan said. "Today, the synthetic leather market is growing because it is less expensive and easier to use. As far as we know, this is the first time anyone has managed to make synthetic leather that is not only water resistant, but also super lichen-repellent – repels water- and oil-based liquids."

Synthetic leather is made of fabric coated with plastic, usually polyurethane (PU) or polyvinyl chloride (PVC). Both PVC and PU can be molded into flat sheets with grooves that give it a leather-like texture. Like genuine leather, synthetic leather is somewhat permeable to liquids. Unlike genuine leather, it becomes sticky at high temperatures because the heat softens the plastic surface.

Bhushan specializes in biomimetics, the science of creating materials and processes that mimic nature. Much of his work was inspired by lotus leaves, whose rough surfaces repel water naturally.

As in their previous experiments that created water- and oil-repellent surfaces, the researchers tried to create a bumpy texture by spraying a layer of silica nanoparticles onto the surface of the synthetic leather.

But Bhushan and PhD student Dev Gurera quickly discovered that plasticizers in synthetic leather — that is, the chemicals that give plastic its plasticity — prevented nanoparticles from sticking, especially inside leather-like grooves. So they cleaned the surface with an ultraviolet light treatment commonly used in the manufacture of computer chips.

The result: nanoparticles adhered to clean synthetic leather, creating a bumpy surface. The researchers then sealed the nanoparticles with a silicone resin. The coating was mostly transparent, so the leather-like texture was still visible.

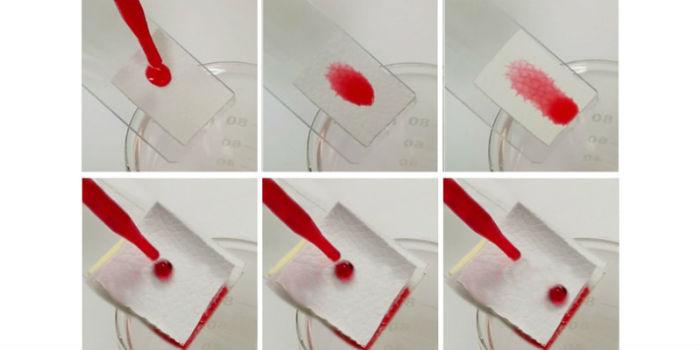

Bhushan and Gurera covered PU and PVC samples and tested them for water and oil repellency and self-cleaning properties, as well as durability and heat resistance.

They squeezed drops of oil and water onto the synthetic leather and tested how much the surface would have to tilt for the drop to fall off. The water rolled with an inclination of 2 degrees and oil with an inclination of 4 degrees. Any inclination below 10 degrees is considered super lichenfuge.

To see how wear affected the coating, the researchers scratched a groove on the surface by dragging a small sapphire bead back and forth over it 100 times. The angle of inclination required to make the droplets roll from the striped surface increased to 7 degrees, still super lichiphobic, but only when the droplet rolled (i.e. perpendicular to the direction of) the worn groove.

When the leather was placed so that the drop had to roll inside the worn groove, the angle required for the drop to roll increased to 44 degrees. That sounds pretty bad, but it's still better than untreated PU and PVC surfaces, which remained coated with water or oil even when tilted at 90 degrees.

To test self-cleaning, the researchers sprayed black silicon carbide powder onto the leather and measured the amount of dust that could be removed with a single drop of water. In untreated synthetic leather, water carried about 10 percent of the dust, while in treated leather, 90 percent of it was removed by washing.

Source: Ohio State University.

Leave your comment