Interesting developments and novelties in coalescing for paintings have been known. Let's learn more about the subject with the support of an expert.

Interesting developments and novelties in coalescing for paintings have been known. Let's learn more about the subject with the support of an expert.

By Inpra Latina

With all the existing regulations to improve the processes and results of paints, especially in the environmental and performance issue, companies have been working the development of products that are up to the demands.

One of those is the coalescents. Coalescence, which has its origin in the Latin word coalescens, is the property that things have to merge or unite. Coalescing substances or materials are those that can be joined into a single body. In the case of coalescing paints, these are binders that help film formation in adverse conditions, such as low temperature and high humidity.

To learn about the main functions of this class of solutions, as well as their correct use in the formulation of paints, we invite Marcos Basso, Market Development Manager for Latin America of Eastman Chemical Company, to this interview:

Inpra Latina: What are the main functions of coalescing in paintings?

Marcos Basso: Coalescing must have certain properties to provide broad effectiveness. Here are some of those properties:

• Low solubility in water: water-miscible coalescings are distributed between the polymer phase and the aqueous phase. The more hydrophilic the coalescing, the greater the tendency it will have to divide in the aqueous phase. As the paint film dries, water evaporates from the film and all the coalescing left in the aqueous phase will go into the environment, which will cause a reduction in its efficiency. The most water-insoluble coalescings are divided into polymer particles. Therefore, the loss during water evaporation is minimized. In addition, water-insoluble coalescings are less likely to migrate into porous substrates.

• Evaporation rate suitable for the application: the evaporation rate must correspond to the particular application. If a coalescing with a very slow evaporation rate is used in a formulation with low PVC content, problems such as blockages, among others, can be caused. Conversely, if the evaporation rate is too fast, problems can be caused in conditions of high humidity, in which the release of water from the paint film is delayed. In that case, the evaporation of the solvent is relatively little affected by moisture, so the solvent could evaporate faster than water, and this would prevent subsequent coalescence.

• Excellent hydrolytic stability: Hydrolytic stability is a measure of coalescing stability with respect to pH, in particular, high pH. Hydrolysis can cause decreased stability in the can, cause odor and even generate antifouling properties, since many biocides work only within a tight range

of pH.

• High efficiency in coalescence with a wide variety of latex emulsions

Inpra Latina: What kind of new developments in coalescing are known for the paint industry?

Marcos Basso: Today, the entire paint chain is looking for different properties that complement each other; society wants products that are less harmful to the environment, the final consumer, simpler, more resistant products that require less maintenance and are also lower odor, in the end, the paint formulator looks for products that meet those needs but that maintain all the properties already conquered, also maintaining their paint at a competitive cost.

Inpra Latina: In the formulation, how should the coalescing workers work in the paints to achieve an excellent product?

Marcos Basso: The minimum film-forming temperature (MFFT) of latex is the most important factor to consider when determining the optimal coalescing level. Harder polymers have higher MFFTs so, to achieve the same level of coalescence, the use of more coalescence is required than in softer polymers.

To determine the initial level of coalescing addition, the response of latex, in particular, to the addition of coalescing with an MFFT bar should be evaluated. To further optimize the levels of the coalescing in the paint, the fundamental properties of the paint at different levels of coalescing can be evaluated. A simple rule to have a well-coalesced film would be to add the equivalent of 10% of the emulsion solid. Example: if we use in a latex paint formulation, 12 parts of an emulsion with 50 percent resin solids, the approximate amount of coalescing will be (12X50%X10%= 0.6 parts).

Inpra Latina: What are the technical characteristics of the coalescing formulated by Eastman?

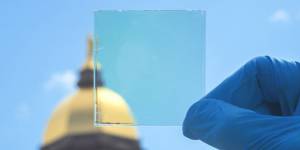

Marcos Basso: Texanol, which is a reference for the formulator of water-based architectural paints provides: Low solubility in water (<0.1%), resulting in a higher efficiency of the associative thickener; compatibility with a wide range of latex; The relative evaporation rate of Texanol is 0.002 (Butyl Acetate = 1), which makes it ideal for most water-based architectural paint applications; provides superior resistance to the washability and abrasion of the paint film and is Zero VOC by Directive 2004/42/EC of the Council of the European Union, which is already adopted in several countries of Latin America.

In the case of the Optifilm 300, in addition to providing the same benefits as Texanol, it is a coalescent of very low smell and also ZERO VOC, both for the European Directive, and for the regulations of the Green Building Council (GH-11) that regulates sustainable constructions.

Inpra Latina: What kind of mistakes should paint formulators not make with the use of coalescing?

Marcos Basso: A formulator, in order not to make a mistake when choosing a coalescing, must take into account all the properties already described above, and also ensure that the supplier is a recognized company in the market, with a long history of quality products and continuity in the supply of the product in their country.

Inpra Latina: What is the process of creating these coalescings like?

Marcos Basso: Eastman has an extensive and intense process for the creation of all its products and that process always begins with a continuous analysis of the needs of society, the formulator and the end customer, who is always looking for something more.

Inpra Latina: How is Latin America in the correct use of coalescing for paintings?

Marcos Basso: The water-based architectural paint formulator in Latin America has always looked for products that can differentiate it in the market in which they have a stake, maintaining a level of quality and competitive price. In recent years, Latin American society has organized and has been establishing regulations such as the limitation of VOC in paints and the prohibition of the use of lead, to guarantee a more sustainable future for all.

Inpra Latina: How is Latin America in the consumption of coalescents?

Marcos Basso: The consumption of coalescents in Latin America has varied from region to region, as it is related to the production of architectural paintings, while Brazil in South America has presented a decrease in the production of paints in recent years, Central America and the Caribbean exhibit good growth. In general, the expectation shared by experts in the segment is for growth of around 2.1% in the coming years.