In the first part of this article the meanings of drying and curing were explained. Next, the different time phases of both terminologies will be mentioned, starting with their quantification.

In the first part of this article the meanings of drying and curing were explained. Next, the different time phases of both terminologies will be mentioned, starting with their quantification.

by Jordi Calvo Carbonell*

In order to be able to have comparable values during the formulation process and to be able to indicate to the user the time necessary to obtain the final characteristics of a painting, definitions have been established to determine the drying and curing times.

Drying times

You can find different rules that perfectly define the drying time. ASTM D1640 and ISO 1517 define drying times. The following is an approximation to these values:

- Dry to dust: The paint is dry to dust when the displacement of the middle finger, without pressure, on the paint leaves no trace. To carry out this test, the support of the finger is made outside the paint film and the sliding is also finished outside it.

- Dry to the Touch: It is considered that a paint is dry to the touch when without making any pressure the middle finger is put in contact with the paint film and no trace is left when removing the finger.

- Total Dry: Total drying is obtained when making a gentle pressure with the middle or index finger on the film is painted no trace is left or stickiness is observed.

- Dry Hard: The hard dry occurs when you can apply the tip of the thumb on the paint exerting a strong pressure and turning the finger 180ºC no footprint is observed on the surface.

These definitions were established at the time for oxidation drying products. The reader will observe that these definitions are quite subjective which can lead to important variations in the values obtained especially when the determinations are made by different people.

Curing times

In films or films resulting from a two-component paint or a component cured by moisture, oxidation and even in physical drying paints such as dispersion paints, nitrocellulosic lacquers, etc. two perfectly differentiated states must be contemplated, the first is when the film once dry has completely lost its stickiness and the second when the film has acquired the final characteristics for which it was designed.

Drying or loss of stickiness: It is obtained by evaporation of solvents and by a sufficient advance of the reaction that entails what we could call unorthodox "drying". The measurement of this time can be done following the same method indicated in the drying times section.

Curing or drying end point: The time needed for the reaction of the components of a paint to be complete depends on the type of paint and the conditions in which it is produced, in many cases it can last several days or even weeks. Their determination should be carried out by means of the corresponding tests in order to be able to verify the point at which there are no changes in their characteristics.

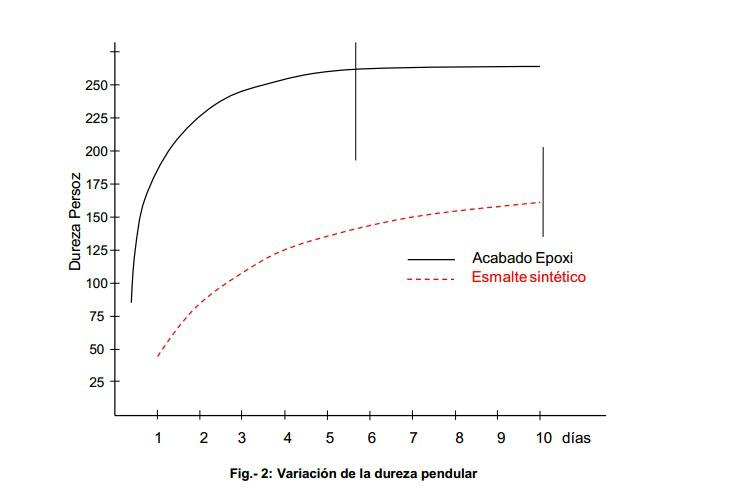

If you look at the characteristics of a polyurethane paint or an epoxy paint, you will see that the brightness, hardness, flexibility, etc. change over time. Note Fig.-2 which corresponds to the hardness of a film of an epoxy finish and a synthetic enamel determined during the first 10 days after application. In the axis of abscissas the elapsed time is indicated, 8 hours, one day, two, up to ten, in the axis of ordered the pendulum hardness. It is easy to see that the total curing occurs differently in each case, while in the epoxy finish from six days the hardness remains constant, in the synthetic enamel the final hardness is obtained with posterity at 10 days since although in small proportion it continues to increase.

Fig.- 2: Variation of pendulum hardness

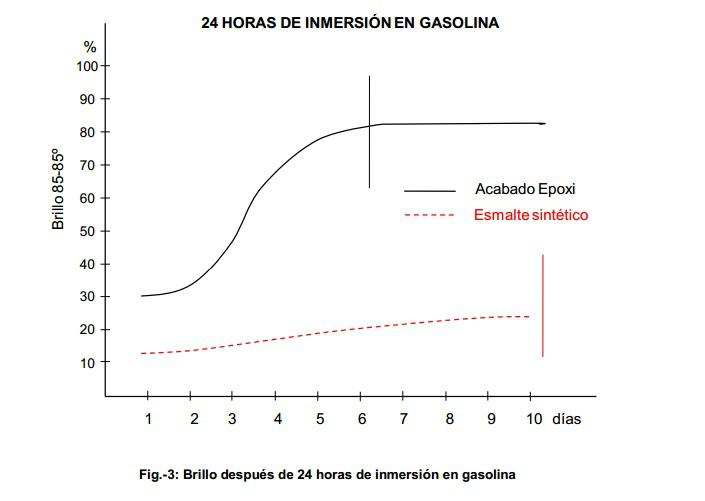

If the same paints are taken and subjected to an immersion in gasoline for 8 hours and the brightness is measured, it is clearly observed, in Fig.-3, that while the epoxy finish each day that passes after its application has a greater resistance and therefore a lower loss of brightness reaching its maximum between six and seven days, synthetic enamel, which by itself has a much lower resistance, has an increase that tends to stabilize but does not find the end point in this period of time.

Fig.-3: Brightness after 24 hours of immersion in gasoline

Terminology considerations

Obtaining the final characteristics: Once the differences between drying time and curing time have been exposed, there are cases in which it should be reflected whether the use of the word drying is the most correct or should, at least in the field between technician and the applicator, use a different terminology. Without pretending an exhaustive relationship, we will take the following examples:

1. Paints based on thermoplastic polymers in dispersion.

2. Alkyd enamels and primers.

3. Polyurethane enamels and primers.

4. Epoxy finishes and primers.

5. Lacquers and nitrocellulosic bottoms.

6. Polyurethane lacquers and bottoms.

7. Paints based on cycled rubber and chlororubber.

8. Unsaturated polyesters and monomers catalyzed with peroxides.

9. Radiation cured finishes.

10.Baked drying enamels and primers.

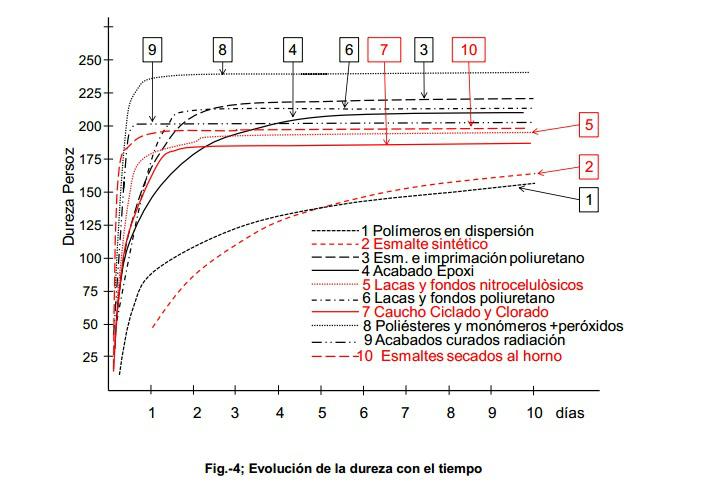

In the graph in Figure 4 you can see the evolution of pendulum hardness in the cases exposed.

Fig.-4; Evolution of hardness over time

Lines 5, 7, 8, 9 and 10 that correspond to nitrocellulosic bottoms or lacquers, paints of cycled or chlorinated rubber, unsaturated polyesters and cured monomers catalyzed with peroxides, bottoms or finishes by radiation, and enamels and kiln-drying primers have in common the obtaining of the final characteristics in a short period of time between a few minutes and several hours.

The first two reach the final characteristics by evaporation of solvents while the last three do so through a chemical, photochemical reaction and the last between an amnic resin and an alkyd or acrylic resin.

On the other hand, lines 1 and 2 that correspond to a plastic paint (polymer in dispersion) and in the other a synthetic enamel, require to reach the final characteristics times greater than 10 days (in most cases more than 20 days) The first dry by evaporation of solvents (coalescing) and the second does so by reaction of oxygen from the air on the conjugated double bonds of the alkyd resin.

Finally, lines 3, 4, 6, corresponding to finishes and primers of polyurethane, epoxy and polyurethane lacquers and bottoms resulting from a chemical reaction require between 3 and 7 days to obtain their definitive characteristics.

Generalizing, in the process of obtaining final characteristics, it is easy to observe that the classification between drying and curing cannot be done exclusively according to whether there is a chemical reaction or simply an evaporation of solvents occurs.

Common nomenclature for technicians and users

On many occasions the user sees their expectations frustrated because the terminology used by the paint manufacturer is not explicit enough or simply not understandable for their knowledge.

In practice, a nomenclature must be found that is understandable to both the technician and the applicator or consumer of the paint, terms that are easily understood and that clearly indicate the state in which the paint is located. It is important that it is defined, "Dry for handling" or the painted object can be handled without spoiling the applied coating and "Dry for commissioning" which corresponds to obtaining the final characteristics of the coating.

These definitions are understandable to anyone whether technical or user. A plastic paint, for interiors or exteriors, based on dispersion polymers will have a "drying for handling" that is, it will not have stickiness in 15 – 20 minutes but will not reach the maximum resistance to wet rubbing until 20 days.

Similarly an epoxy paint for garage floors will have a drying without stickiness between 6 – 8 hours, however it will not reach its total resistance to gasoline, brake fluid, oil, etc. until 8 days after its application therefore the "Drying for commissioning" will be 8 days.

Between the assessment of the technician and that of the user, a balance must be reached that allows both to maintain an effective dialogue and in turn understand the meaning of each term used.

Approach to practical definitions

If the common language for good understanding between technicians and users is sought, it is necessary to determine the needs of the latter and for this it must be defined:

- Drying to the touch: Corresponds to the time needed, from the application, so that the coating can be touched slightly without leaving a trace on it.

- Drying for repainting: It is the time necessary so that the application of the second layer does not harm the characteristics of the first.

- Drying for handling: The painted object can be manipulated without impairing its appearance.

- Drying for commissioning: It is the time needed from the application for the coating to reach the final characteristics for which it has been designed.

The names used can be those that have been indicated or others but they must perfectly define the situations exposed.

Note that in the application of a plastic paint the user has a tendency to apply the second layer of paint as soon as he can touch the paint without staining, this means that in most cases the application is done with an interval of 1 to 2 hours. The drying to repaint in most cases should be at least six hours, this would lead to an increase in the covering power and in the case of satin or glossy paints higher level and homogeneity of brightness.

The applicator, in many cases, verifies the washability of the paint by rubbing it with a moistened finger and does so after a few hours of application. It is necessary that the information you receive tells you that the maximum resistance to wet rubbing is obtained after 20 days of application and therefore that the tests will be all the more real the closer you are to the time that has been defined as "Drying for commissioning".

In the same sense, an epoxy paint for floors despite having a "Drying for handling" in 6 or 8 hours will have much greater resistance after several days of its application.

Conclusions: drying or curing?

It has been seen in the previous paragraphs that there is no perfect correspondence between the times of obtaining the final characteristics and the fact that the process is by simple evaporation of solvents or by a chemical reaction.

At a strictly technical level it is correct to use the word drying to indicate the evaporation of solvents and obtain the final appearance such as the lack of stickiness, shine, etc. while curing is used to indicate that it has been produced by a complete chemical reaction and that the characteristics of the coating are already definitive, but in this case we should consider whether oil paints, alkyd paints and oven drying paints dry or cure.

When it comes to transmitting to the user a message that entails the idea that the product must be applied under certain conditions, that the mixture after a certain time must be discarded, that the repainting between 12 layers must be greater or less than a certain time and the difference between when it is manipulable, passable, etc. or when the product has already obtained the final properties, it will be necessary to use a common and understandable language for both the technician and the user.

It is important and should be considered the need to use in the dialogue of the technician with the user and in the elaboration of the technical information of each product a vocabulary whose definitions are clear both with respect to the drying times and those that refer to the useful life or pot-life, repainting time between layers or those that entail improvements or losses of quality in the applied paint.

* Jordi Calvo is a chemical engineer, member of the Board of Directors of AETEPA (Spanish Association of Paint and Allied Technicians) and author of the book "Paintings and Coatings: Introduction to their technology".

Leave your comment