A review to highlight some of the most important innovations in the use of inactive pigments.

A review to highlight some of the most important innovations in the use of inactive pigments.

by M.Sc. Ph.D. Julián A. Restrepo R.*

I declare myself passionate about the world of coatings, a world that fascinated me for almost 15 years when I began my final degree project to obtain my degree as a Chemical Engineer: I saw a whole universe of possibilities in the use of such a diverse amount of materials, their multiple potential combinations, their functionalities, the possibility of resorting to various disciplines and analysis techniques, Anyway. From that moment I was captivated and I have been fortunate to be able to carry out my professional career in this field.

I also declare myself passionate about history, in fact, I have a previous collaboration under the title: "Anecdotes of the history of paintings" [1], but I always wanted to write an article that showed various very innovative ideas that have contributed the manufacturers associated with the world of paints and coatings, and that allow to optimize and maximize the potential of many of the raw materials used in paints.

This article therefore aims to discuss very briefly, some great ideas and innovations related to various inactive, inert or "functional loads" pigments (inorganic thickeners, titanium dioxide extensions) used in the paints and coatings sector and whose uses, in the opinion of the author, constitute very creative and innovative ideas, and in other cases solve in a very simple way various associated formulation problems.

Inactive pigments [2]

Inactive pigments are those that "have no optical activity" in the coating, since by definition they do not provide color and opacity, but they have a much lower price than that of active pigments (such as that associated with titanium dioxide and other organic pigments, for example), and are mainly used to lower the cost of paints. The general name used to designate the type of pigments that do not provide color is that of inactive pigments, inert pigments or simply fillers.

But despite being referred to only as fillers, by careful selection of a specific type of inactive pigment, for each particular type of coating, in some cases, certain properties of the coating can be improved. That is, the proper selection of the inactive pigment at the formulation stage, can improve different properties, such as viscosity, fluidity, rheology, permeability, hardness, washability and abrasion resistance; as well as conveniently favoring the sedimentation conditions in the container during the storage time, in order to avoid or reduce it to the maximum. Certain loads mechanically reinforce the structure of the dry film, while others increase its resistance and especially to the penetration of moisture through it.

In these cases where inactive pigments are not only limited to lowering the cost of paints, but also provide additional effects and properties, they are called "functional loads"; that is, its function is not limited to reducing the cost of painting, but to providing additional beneficial properties to it.

Such is the case of extensions, as a partial substitute for the active pigment. But there are other series of functional loads (in some cases considered as additives, according to the dose used), such as some rheological and anti-decanting agents (bentonites and hectorites, as will be discussed later), matting agents (silicas), corrosion inhibitors (phosphates, hydroxyphosphites, phosphosilicates), among others; but the cost of these functional loads is, in many cases, higher than that of active pigments; that is, although they do not provide color, they provide other advantages that are highly appreciated by formulators and for which they are hardly surpassed by other materials.

Innovations in the use of inactive pigments

Below I will present and briefly discuss a short list of inactive pigments used in the paints and coatings industry, in some cases, for many years now, but where, in reality, the coating formulation technician does not know that in order to use them various and difficult production or associated formulation problems have been solved, or that with its use, many problems are solved.

1. Rheological modifiers, Bentones type: Current commercial Bentones, commonly called Bentonites or bentonitic thickeners, are a range of rheological modifiers used in both solvent-based systems and aqueous systems and used to rheologically modify a paint: to increase or provide thixotropy, as anti-sedimenting agents, to decrease splash, thicken or increase the consistency of the product.

Bentones are obtained through the chemical modification of natural Bentones, which come from clays (rocks of volcanic origin and pyroclastic rocks) [3], of very fine particle size (colloidal), being part of the family of smectites, montmorillonites, hectorites, sepiolites, atapulguitas, among others. Its name comes from a site located in Fort Benton, United States [4]. Naturally, this type of clay has the property of absorbing a large amount of water and swelling, retaining it.

The objective of chemically treating Bentones (by modifying them organically, using quaternary ammonium salts), is to provide polarity and high compatibility in organic media. It is highlighted here, the fact that it has been achieved that the Bentone that previously absorbed water and swelled with it, now absorbs and swells with solvents (whether aromatic or aliphatic, this depending on the type of quaternary salt used). Commercial examples are in the Bentone® brand of Elementis Specialties.

The issue is that this type of materials have been very studied, finding, in addition, interesting associated properties:

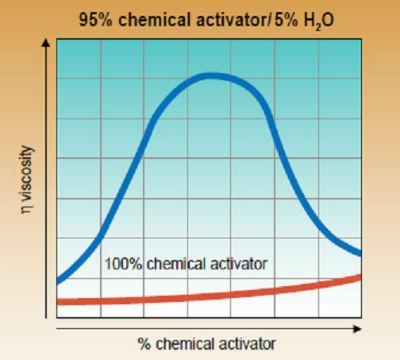

a) Use of polar activators in solvent-based systems: Water is an enemy for most solvent-based systems, as it can cause surface defects such as crater, pores, pin-hole points, bubbles, non-uniform brightness, veils, among others, but in the case of Bentones for solvent-based applications, manufacturers found that the addition of a small portion of what they call a "polar activator", which is nothing more than a mixture of a polar hydrocarbon solvent (either an alcohol or acetone) with a small portion of water, significantly improves the performance of said bentone, which is reflected in an appreciable increase in viscosity to an optimal point, as can be seen in Figure 1. This without affecting the performance of the coating or causing surface defects.

Figure 1. Performance of a Bentone as a thickener in a typical solvent-based system:

(a) Red curve: bentonitic system without polar activator; b) Blue curve: bentonitic system added with polar activator [Images taken from ref. 5].

b) Formation of pregels in solvent-based and water-based systems: It has been found that the performance of Bentones can be significantly improved through the manufacture of pregels (production of a ready-to-use bentone concentrate): a) in the case of solvent-based systems, approx. 10%, including the addition of the "polar activator"; b) for water-based systems, the concentration is between 3-5%. This allows a complete incorporation and activation of bentone, in addition to the fact that by remaining stored for some time as an intermediate product for the manufacturing process, "the intermediate is allowed to mature", be moistened and activated completely, appreciably improving its performance, and allowing to lower costs, manufacturing time and defects in the product (greater homogeneity).

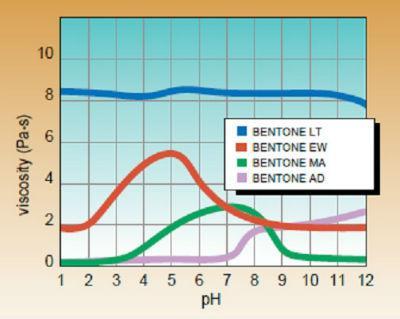

c) Influence of pH in aqueous systems: Aqueous systems are shown to be more complex than solvent-based systems, being, for example, sensitive to the pH of the medium. Figure 2 shows different references of aqueous Bentones that show a maximum viscosity at different pHs.

Figure 2. Effect of pH on the final viscosity of different pregels of aqueous Bentones (3% by weight, 50 rpm): a) Blue curve: Bentone not dependent on pH (range of use, pH: 6-11); b) Red curve: Bentone showing optimal viscosity at pH = 5; c) Green curve: Bentone showing optimal viscosity at pH = 7.5; d) Violet curve: Bentone showing increasing performance for pHs> 7 [Images taken from ref. 5].

Note: In the second part we will continue to develop this article mentioning the use of pigments type "Hollow Spheres" and the use of Diatomaceous Silicas (diatoms).

[1] a) Restrepo, J.A., "Anécdotas de la historia de las pinturas, parte I". Inpralatina, Vol. 19, No. 2, Mar/Apr 2014 pp. 16-20; b) Restrepo, J.A., "Anécdotas de la historia de las pinturas, parte II". Inpralatina, Vol. 19, No. 3, May/Jun 2014 pp. 15-18; c) Restrepo, J.A., "Anécdotas de la historia de las pinturas, parte III". Inpralatina, Vol. 19, No. 4, Jul/Aug 2014 pp. 19-22.

[2] a) Restrepo, J.A., "Inactive pigments in formulation. Part I." Inpralatina, Vol. 17, No. 1, Jan/Feb 2012, pp. 21-25; b) Restrepo, J.A., "Inactive pigments in formulation. Part II". Inpralatina, Vol. 17, No. 2, Mar/Apr 2012, pp. 18-21; c) Correa, G. and Orrego, J., "Minerals are metallic in the coatings industry". Inpralatina, Vol. 4, No. 4, August/September 1999, pp. 20-26

[3] Karakaya, M.C.; Karakaya, N.; Bakır, S., "Some properties and potential applications of the Na- and Ca-bentonites of ordu (NE. Turkey)". Applied Clay Science, 54 (2011), pp. 159-165

[4] https://en.wikipedia.org/wiki/Bentonite

[5] Rheology Handbook by Elementis Specialties, 2005.

* Julián A. Restrepo R. is an Advisor and Technical Consultant in Coatings CoatingXPERTS. [email protected] Medellin, Colombia.

Leave your comment