International. Researchers have developed an ultra-thin, non-toxic, lightweight, and edible coating that could be used to make brighter paints and coatings, for use in the cosmetic, food or pharmaceutical industries.

International. Researchers have developed an ultra-thin, non-toxic, lightweight, and edible coating that could be used to make brighter paints and coatings, for use in the cosmetic, food or pharmaceutical industries.

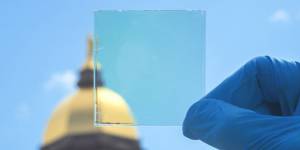

The material, which is 20 times whiter than paper, is made of non-toxic cellulose and achieves such a bright whiteness by mimicking the structure of the ultra-thin scales of certain types of beetles.

Bright colors are usually produced using pigments, which absorb certain wavelengths of light and reflect others, which our eyes perceive as color.

In order for it to appear as white, however, all wavelengths of light must be reflected just as effectively. Most commercially available white products, such as sunscreens, cosmetics, and paints, incorporate highly refractive particles (usually titanium dioxide or zinc oxide) to reflect light efficiently. These materials, while considered safe, are not fully sustainable or biocompatible.

In nature, the Cyphochilus beetle, which is native to Southeast Asia, produces its ultra-white coloration not through pigments, but by exploiting the geometry of a dense chitin network, a molecule also found in mollusk shells, insect exoskeletons, and fungal cell walls. Chitin has a structure that scatters light extremely efficiently, resulting in ultra-white coatings that are very thin and lightweight.

"White is a very special type of structural color," said paper co-author Dr. Olimpia Onelli, from Cambridge's Department of Chemistry. "Other types of structural color, for example butterfly wings or opals, have a specific pattern in their structure that results in a vibrant color, but to produce white, the structure must be as random as possible."

The Cambridge team, working with researchers at Aalto University in Finland, mimicked the structure of chitin using cellulose, which is non-toxic, abundant, strong and biocompatible. Using small cellulose filaments, or cellulose nanofibrils, they achieved the same ultra-white effect in a flexible membrane.

By using a combination of nanofibrils of different diameters, the researchers were able to adjust the opacity and therefore whiteness of the final material. The membranes made of the thinner fibers were more transparent, while the addition of medium and thick fibers resulted in a more opaque membrane. In this way, the researchers were able to adjust the geometry of the nanofibers so that they reflected the most light.

"These cellulose-based materials have a structure that is almost spaghetti," which is how they can scatter light very well," said lead author Dr Silvia Vignolini, also from Cambridge's Department of Chemistry. "We have to get the right mix: we don't want it to be too uniform, and we don't want it to collapse."

Like beetle scales, cellulose membranes are extremely thin: only a few millionths of a meter thick, although the researchers say even the thinnest membranes could be produced by further optimizing their manufacturing process. The membranes scatter light 20 to 30 times more efficiently than paper, and could be used to produce bright, sustainable, and biocompatible efficient white materials of the next generation.

Data Source Provider: University of Cambridge.

Leave your comment