International. EU-funded researchers have developed a highly productive and environmentally friendly method for manufacturing powder gel coatings for new composite molds.

International. EU-funded researchers have developed a highly productive and environmentally friendly method for manufacturing powder gel coatings for new composite molds.

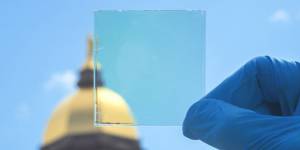

With the emergence of composite materials that have formed a very valuable class of materials for engineering, today gel-shaped coatings are applied to give a high-quality finish to the visible surface of fiber-reinforced composite materials that are later used to manufacture complex parts by molding.

This innovation for industrial manufacturing, the result of the EU-funded Ecogel Cronos project, will be of interest to those who manufacture vehicles in series. Composite materials have been identified as an essential enabling technology to meet the requirements of weight, cost and speed of production. Another high-tech sector that is called to benefit from this novelty is aerospace.

Within the project, different manufacturing techniques have been developed and suitable additives have been selected in order to obtain coating formulas, in the form of powder gel, very reactive, stable and cost-effective. The new process has been shown to reduce the manufacturing time of the gel coating and also pollutant emissions during production.

Tests were carried out on the use of composite-based parts in tractor and car doors. By means of modelling exercises, the thresholds of electrical conductivity were determined. In one of the tests, it was possible to obtain a powder gel for coating completely finished in a period of 80% less than conventional liquid gel coatings.

This three-year project, scheduled for completion by the end of August 2016, is currently focused on developing new composite molds for carbon fiber sheets. While to obtain the conventional composite materials used in the automotive industry, a technology of high cost and aerospace origin has been used as a rule (the so-called molded composite sheet technique or SMC), the ECOGEL CRONOS project focuses, for its part, on the technique of resin transfer molding (RTM) in an attempt to increase efficiency in costs and production, maintaining performance and quality.

Its new RTM process, consisting of reusable, thermally regulated coating layers with electrical conductivity, allows release agents, gel coatings and fibers to be applied to the composite layer while another is being injected. In this way, it is possible to increase production with a relatively low additional investment. A mould has been built for the pilot plant and tests are already underway.

With information from http://cordis.europa.eu/

Leave your comment