In addition to an additive with a very attractive rheological modification, a solution is required that allows improvements to be achieved during the formation of the film and potentiate the properties of the cured film.

By Oliver Peña*

At present, it is of utmost importance to have biodegradable and sustainable alternatives that help create more environmentally friendly products. The Mexican market requires solutions that, in addition to these characteristics, provide additional advantages and benefits to the final products.

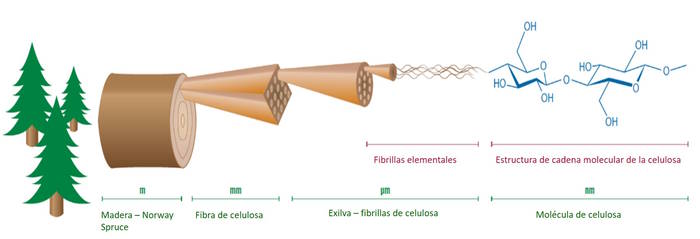

There is a new technology that is made from the microfibrillation process to which the wood of the "Norway Spruce" tree is subjected. Due to its origin and composition, this material can be considered biodegradable, sustainable and renewable. It is important to mention that the possible ecological damage that would represent the felling of these trees is mitigated thanks to the fact that two trees are planted for each tree felled.

In Mexico, First Quality Chemicals is the official distributor of Exilva de Borrregaard, which is a multinational company known for having the most advanced biorefinery globally, because in addition to Exilva they obtain various products for different industries of the same raw material.

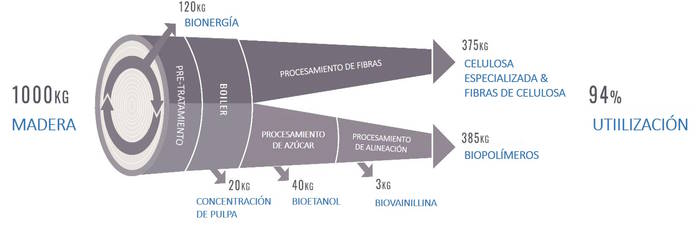

This transformation process reaches 94% of use; That is, for every 1,000 kilograms of wood obtained, 940 kilograms are used effectively.

Image 1. Manufacturing process of Exilva and various Borregaard products

As we can see in image 1, there is a separation of cellulose fibers and sugars present in wood. This allows to guarantee high purity cellulose, which is highly resistant to microbial attack, this being an advantage for Exilva, since it does not require biocides to be stored during its life time.

Exilva is a three-dimensional network of microfibrillated cellulose (MFC), which has a large surface area and a large availability of hydroxyl groups (-OH) in its structure. This allows Exilva to interact physically and chemically with the environment where it is located. Its thickening mechanism is associative.

Image 2: Exilva comes from the microfibrillation of cellulose fibers from Norway Spruce, the fiber diameter reached is micrometric.

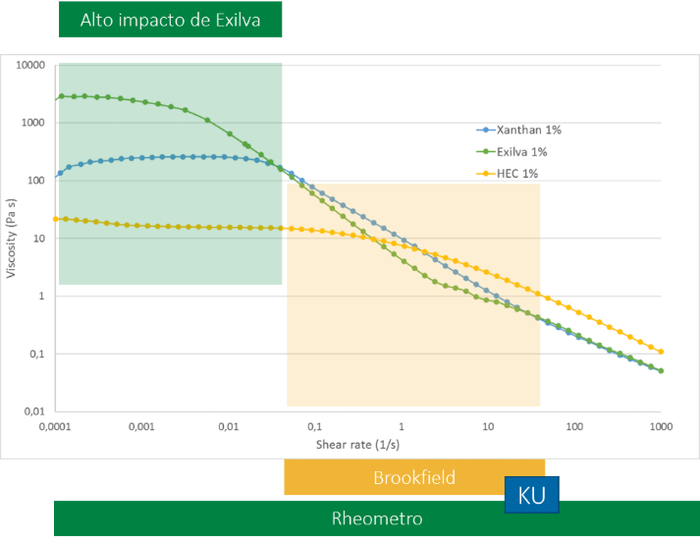

Exilva has a pseudoplastic rheological behavior; That is, its viscosity at rest will be high and will decrease as the shear force to which it is subjected increases. This effect is of great benefit in paints, because it will allow to formulate coatings with a high stability in storage without affecting their handling during the application of the same.

Exilva allows aqueous coatings to regain their viscosity almost immediately after being applied.

Image 3. Comparison of the rheological behavior of Exilva against cellulosic thickeners at 1% active material

You can see in image 3 the comparison of Exilva against other cellulosic thickeners at 1% in total active material. The resting viscosity achieved with Exilva is ten times higher than Xanthan rubber and more than 100 times higher than hydroxyethyl cellulose.

Although the viscosity at rest is considerably higher, the measurements in the KU area are very similar. This is one of Exilva's greatest virtues as a rheological modifier.

Exilva does not only help rheological modification. It is a multifunctional additive that, in addition to generating the rheology analyzed above, allows to considerably reduce synergesis, phase separation and sedimentation during storage of the finished product.

Additionally, it allows to potentiate various characteristics in the applied paint film. These include:

Reduction of stickiness or tack on the surface of the coating.

Improved cracking resistance, even at high film thicknesses.

Improvement in the open time "open time" of the film.

Generation of an "anti-blocking" effect.

Improvement in adhesion to various substrates due to their high availability of hydroxyl groups (-OH).

Increased resistance to wet film runoff without sacrificing leveling.

One of the most recent applications where the performance of Exilva has been analyzed is in the formulation of bases for tintometric systems. As we know, the formulation of bases is a very complex task, because the reproducibility of it must be guaranteed, batch by batch.

Once the base is formulated, it will be inked by universal dyes and subjected to shear efforts to ensure the correct homogenization of the dye at the base.

The incorporation of the ink in the base by itself generates an imbalance in the surfactants of the system and the mechanical stresses applied can also generate a decrease in the effectiveness of the thickeners.

The two previous factors generate variations in the viscosity of the finished product, pigment flotation, among other effects.

Benefits in a Deep Acrylic Base

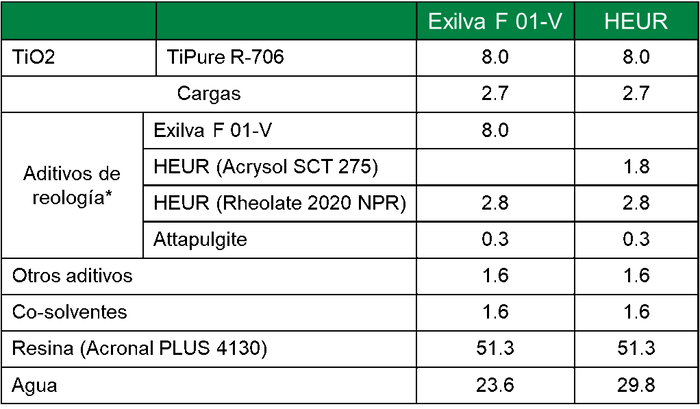

Exilva is a solution to combat viscosity decrease in paints after the inking process with universal bases. Below we will analyze the benefits of incorporating Exilva in an acrylic Deep base. The formulation to be analyzed is as follows:

Exilva is a solution to combat viscosity decrease in paints after the inking process with universal bases. Below we will analyze the benefits of incorporating Exilva in an acrylic Deep base. The formulation to be analyzed is as follows:

Table 1. Formulation to be evaluated with Exilva®, VOC: <50 g/L, solids: 30.0%

It is important to mention that, in this example, Exilva is overdosed. Its recommended dosage ranges from 0.2 to 3% in total formulation, only that analyzing the results with this overdose is interesting due to the results obtained.

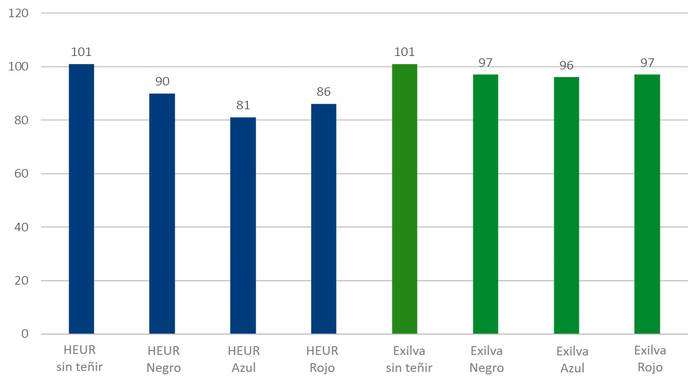

Figure 1. Viscosity in the KU area of Exilva and HEUR systems

We can analyze that, even with exilva overdosed, the viscosity in the KU area is maintained or improved with respect to the thickener of the reference, even when compared with different inks of the system.

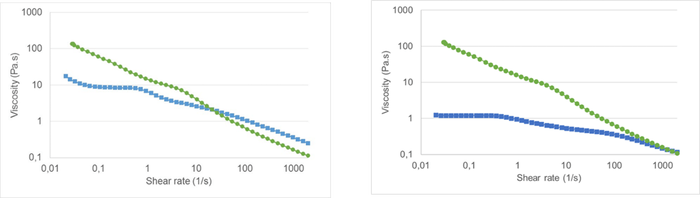

Graphs 2 and 3: The left graph shows the behavior in uninked systems and on the right the systems inked with black. Exilva is represented by the green line

The previous graphs show us the comparison of the rheology of the bases with and without inking. We can see in the area of low shear or rest a fairly high viscosity in the systems where Exilva was incorporated, being a difference of at least ten times for the non-inked base and 100 times in the base inked with black.

Comparing the two green lines, we can analyze that the inking did not cause a considerable rheological modification, which is of great benefit in this type of systems.

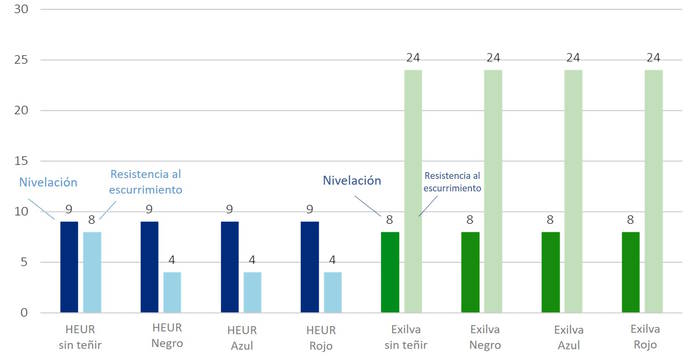

Figure 4 shows the runoff resistance and leveling of the bases studied. Runoff is measured in mills of wet thickness, and leveling is reported on a scale of one to ten, with 10 being perfect leveling.

We can see that the resistance to runoff rose substantially from 8 and 4 mills respectively to 24 mills, and leveling was reduced on its scale from 9 to 8. We can conclude with these results that the resistance to runoff is potentiated (without generating cracking) with a slight sacrifice in leveling.

Figure 4. Evaluation of leveling and runoff resistance of bases with and without inking

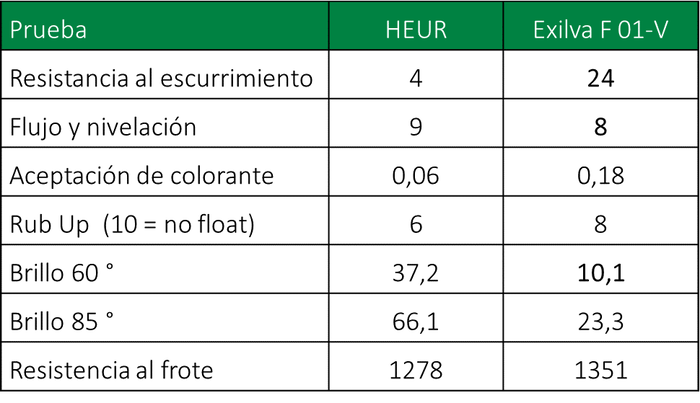

Additionally, other parameters were measured, in order to generate more information about the test performed, table 2 shows the results obtained.

Table 2. Additional parameters in the tintometric base

Dye acceptance, Rub Up test and rub resistance were favored by Exilva, while brightness was affected and its units decreased by 60° and 80° measurement. This is because Exilva is a non-soluble three-dimensional network, and the overdose caused the surface of the applied coating to have some roughness, which generated the matting of the film; But at normal dosage levels, the brightness reduction will be much less.

As we were able to analyze throughout this article, Exilva is not only a rheological modifier, it is also a film property enhancer and product stabilizer in storage. It is completely natural, non-toxic, sustainable and biodegradable. In addition, it is stable at pH values (1-13) and at elevated temperature conditions, allowing Exilva to generate greater robustness in the final formulation.

*Oliver Peña

Technical Service Rep at First Quality Chemicals

[email protected]

Leave your comment