Efficiency, performance, durability are some of the characteristics of the equipment for the application of paints, which seek to facilitate the work of an applicator who must know the new developments to make a correct choice of the system.

Efficiency, performance, durability are some of the characteristics of the equipment for the application of paints, which seek to facilitate the work of an applicator who must know the new developments to make a correct choice of the system.

by Duván Chaverra Agudelo

Advances in application equipment technologies are constantly presented, but the fact that new formulations of paints are presented helps a lot to their development, as assured by the technical manager of the Colombian company Aspintec, Carlos F. López, one of our guests in this edition of INPRA LATINA.

And it is that at the same time with the globalized evolution, the paints and coatings industry does not cease to surprise us with the constant developments, product launches and offers available. This time we will use this space to talk about the application equipment, its new developments, and some recommendations that applicators should take into account before acquiring a system of this class, as there are many previous variants to analyze according to the purpose.

Ricardo Vergara, project manager of OTI Ingenieros de Chile, explained that another important aspect of the evolution of paint application equipment has to do with its adaptation to current environmental trends: "Systems that have higher transfer rates, that need less compressed air to operate, that can work with 100% solid products to not use solvents, in addition to implementing control systems in the efficiency of the machines; decrease in spare parts and greater durability in wear parts, these are some of the advances made. Similarly, in the industry there is interest in the manufacture of equipment for the well-being of operators, such as accessories and elements of less weight, size and more ergonomic shapes. "

On the basic differences that application teams have according to each industry, Ricardo Vergara comments that they are different situations and that each objective is different, so in the same way the process changes.

"The main difference is the motivation or what you want to do with each team. In the case of automotive paint, the main thing is the quality of application, it does not matter neither the speed nor the efficiency but the quality of finish that can be obtained. In industrial painting, the products are mainly coatings where what is sought is to give greater thicknesses in the shortest possible time and also seeks that the team can apply products with higher percentages of solids and higher viscosities that fully comply with the required scheme. And in residential painting there are other motivations: speed, acceptable quality of products with decorative characteristics".

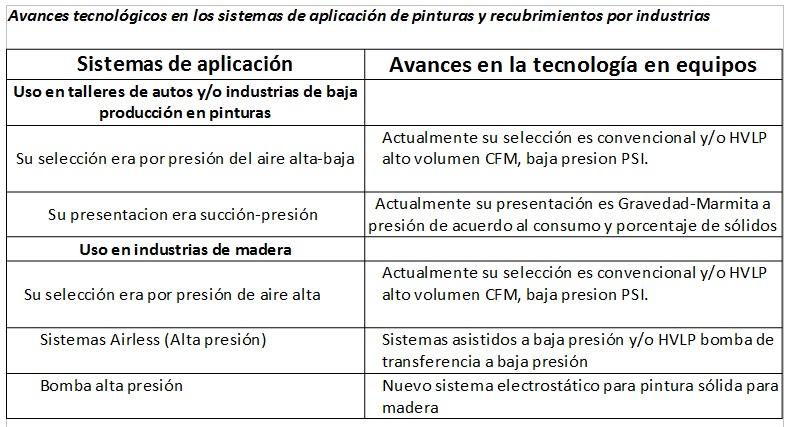

In table 1 we can see how technological advances in equipment have forced to modify the application systems in large industries in the region such as automotive and wood.

For his part, the manager of Aspintec explains in detail the basic components to keep in mind in the selection of a paint application equipment:

- Paint system to be used: type of paint (solid-liquid-solvent-water), percentage of solids of the paint to be used, thickness of film to be achieved, primary layer (bases), intermediate layer, type of finish, objective of the paint layer (protection, decoration), area to be painted in square meters, time to apply in hours.

- Air capacity to paint: take into account the production of the air producing compressor in CFM (Cubic feet per minute) Cleaning and control of the air to be used -diameters of ducts for air passage, type of connectors (without restriction of air passage), lengths of hoses.

- Selection of equipment to use: taking into account the above, the equipment to be used is selected (which must be compatible with the paint to be used as well as with the air capacity required by the equipment). Know the basic components of a paint spray gun as a body and air and fluid controls -fan regulator- air inlet regulator.

- Fluid area: peak and needle, take into account diameter (delivery in c.c), type of material (normal steel, stainless steel and grade).

- Spray area: bushing and/or spray nozzle according to selection system, taking into account both its consumption and working pressure.

- Types of systems: conventional (HVLP, airless, airless assisted, high and low pressure). Electrostatic systems (liquid, solid, induction solid, ionization).

"The applicator painter is the fourth important component to achieve the best performance of equipment to use, this requires knowing what are the technical concepts of the paint (air to use) and the equipment to use, if you do not have this knowledge it is difficult for the selected equipment to give you a good result, "said Carlos F. López, of Aspintec.

Ricardo Vergara's thought coincides with the previous one: "First you must know your machine very well, be careful in cleaning; you must know about the virtues and difficulties that the team presents. In addition, it is important that you always consider the quality of the nozzle you use and whether the product you are going to apply is compatible with the machine you have."

Powder coating equipment

When consulting those interviewed by the powder coating teams, everything seems to indicate that their technological evolution is satisfactory, however, in Chile, for example, the overcost of energy limits its use.

"Powder coating application equipment is very developed, technologically it is at a very good level. In Chile, its commercialization is limited to certain types of applications, since the use of energy in this country has a high value, so many customers decline to use this equipment due to the consumption generated by its curing; in structures of great thickness, you could say that the market is growing, "said the representative of OTI Ingenieros.

In Colombia, according to our guest from the company Aspintec, its development has been reduced: "The application systems of solid paints are very developed in the world, but in the case of Colombia it has been very slow, due to the types of paints present in the market that in some cases lead their use for the price and not for their benefits. In the world there are systems for use on non-conductive surfaces such as wood or plastic. Likewise, for the application of finishes with metallic and figurative loads".

In addition to the above, it is clear that the applicator must take into account the importance of selecting a technical advisor who has extensive knowledge of equipment for painting. But, much more important is that they have a full knowledge of the needs you intend to satisfy.

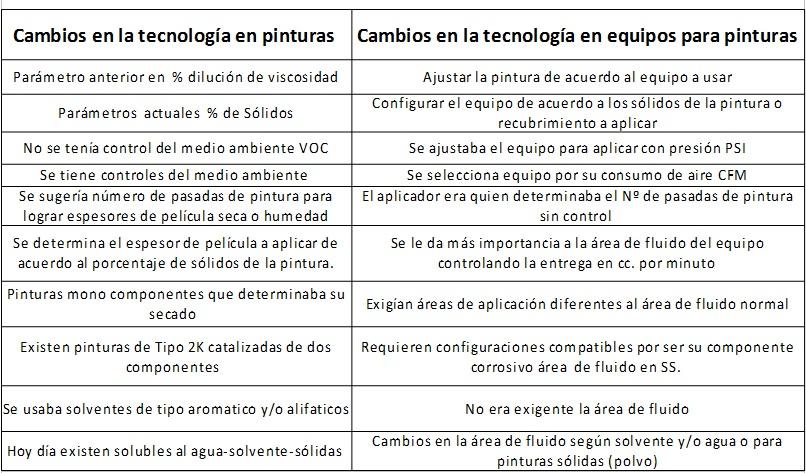

The table shows how the equipment has adjusted to the modifications that occur in the paint formulations.

To highlight

Sales, marketing, sectors of use

Chile and Colombia are evolving markets with important application companies. On the southern side, the project manager of OTI Ingenieros, Ricardo Vergara, explained that the mining and decorative sectors dominate the market for paint application equipment.

"In our country there are two market areas that in our opinion are marketing more equipment: one is the mining industrial area, which acquires large airless equipment, as well as application equipment for two-component products, the most used being those designed for 100% solid fast drying products, as is the case of the polyurea application. The other area is decorative, since the construction market in our country is constantly growing so there are many new players who acquire equipment for the application of paint in construction."

For its part, and according to the experience of Carlos F. López, manager of the Colombian company Aspintec, the price factor and ignorance of what is acquired affects the commercialization of new technologies. "Sales in Latin America continue to be presented on a price basis, so new technologies in equipment are not sold; in addition, the applicator is allowed to make purchases without having any techniques or parameters about the means of application."

In Colombia, according to the guest, the systems that may be leading the market are those of HVLP concept in the automotive and wood. "Many use them because the products are marked with HVLP on the body of the gun, but this is not always real; in addition, it can be said that today they are the cheapest," said the guest.

By Colombian market niche, the metal-mechanical industry leads the commercialization with electrostatic systems, while the Airless remain competitive in the field of Marine, Oil and Industrial maintenance.

Leave your comment