Industrial facilities turn to safer and more effective inorganic coatings to reduce the risk of serious injury and death of coating contractors.

Industrial facilities turn to safer and more effective inorganic coatings to reduce the risk of serious injury and death of coating contractors.

by EonCoat*

For decades, industrial facilities have measured the effectiveness of a coating by its ability to prevent corrosion, which is obviously its fundamental purpose. However, given the growing awareness of the dangers of traditional organic coatings, and the serious health risks these pose to contractors, many facility safety managers are specifying safer, more inorganic options that now exist on the market.

Coating contractors typically perform one of the most dangerous jobs on a plant. Accident reports published by OSHA (Occupational Safety and Health Administration), and available on the U.S. Department of Labor's website look like tragic news headlines: "One dead and two injured when paint vapor bursts," "One employee dies and another is burned in spontaneous paint combustion," "Three employees suffocated by paint emissions."

The risks are even greater in confined spaces such as tanks, vessels, silos, storage tanks, hoppers and vaults: common steel structures, which are found in most industrial facilities, and in which protection against corrosion is essential, Confined spaces are known not only for accumulating emissions and toxic dusts, flammable, and even explosive, but the very act of applying traditional coatings poses serious risks.

The problem lies in the application of carbon-based coatings, including but not limited to commonly used polymers, polyureas, and urethanes. These coatings emit hazardous VOC (Volatile Organic Compounds) and Hazardous Air Pollutants (PAHs) gases, both during and after application, which can cause irritation to the eyes and nose, threaten the airways, cause headaches, nausea, dizziness, memory loss or even loss of consciousness to exposed personnel or contractors.

On the other hand, when applied with a spray gun atomized coatings that have low flash points can cause a fire or even explode. Considering that multi-component spraying equipment uses electrical elements as well as heat, this equipment itself can pose a risk in such an environment.

"Spraying conventional coatings inside a tank is dangerous," warns Tony Collins, an industrial contractor with 30 years of experience. "Spraying atomizes the toxic and flammable coating material, which can have a flash point of just 70°C, the working temperature inside the tank. This means that if a tool falls or a metal object is dragged through the tank and a spark occurs, emissions can ignite and explode. I am surprised that this practice is legal."

Unfortunately, the risk is not limited to a single type of work. Coating contractors who are constantly exposed to volatile organic compounds over time can develop chronic health problems, ranging from liver, kidney, and nervous system involvement to asthma and certain types of cancer.

To address the numerous risks and improve worker safety, working in confined spaces is regulated by OSHA's Code of Federal Regulations 29 CFR 1910.146. Unfortunately, as the investigation of new accidents continues to show, many of the safety measures are not properly followed.

New inorganic coating options

Fortunately, in the last decade the technology of coatings has changed drastically. A new category of inorganic phosphate chemical cements (CBPCs) has been created that do not emit volatile organic compounds or PAHs, during or after application, have no flash point, do not produce flame propagation, and must not comply with regulations for the disposal of hazardous waste.

Some of these coatings, such as EonCoat, manufactured by the company of the same name, do not contain toxins of any nature that can cause problems, either when touched, consumed or inhaled.

The ceramic coating consists of two non-harmful components that do not interact until applied by a multi-component spray gun. Since the components are not mixed and are not put together before application, there is no need to use hazardous ingredients that produce VOCs in the formulation, nor hap.

Ceramic coatings do not generate smoke and have a flame propagation rate of zero, which means that flames do not move across the surface. In fact, an intense flame can be exposed directly to the coated surface and the substrate does not ignite unless enough heat is generated to cause the substrate behind the coating to ignite. Because it has no flash point, the coating cannot catch fire or explode during spray gun application.

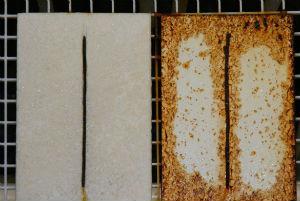

As for their corrosion resistance properties, ceramic coatings pass the test outstandingly.

Unlike conventional polymer coatings, which sit on top of the substrate, the coating in question adheres to the substrate through a chemical reaction, and a slight oxidation of the surface actually improves the reaction. This makes it virtually impossible for corrosion promoters, such as oxygen and moisture, to sit behind the coating, as they can with current coatings.

The corrosion barrier is covered by a layer of real ceramic, resistant to fire, water, abrasion, chemicals and corrosion.

Thanks to the availability on the market of new, safer inorganic options, coating experts as well as asset and industrial safety managers can now specify an alternative to conventional carbon-based coatings, which will dramatically increase safety without sacrificing corrosion protection.

"Looking at the market and the level of safety and environmental awareness the industry has gained, there is no excuse to use toxic and flammable materials when there is another option," Collins says.

* For more information about the company you can write to the email [email protected]; or visit the website: www.eoncoat.com