Consider the main existing criteria for the identification of a type of corrosion. Below we will present some outstanding parameters in this aspect.

Consider the main existing criteria for the identification of a type of corrosion. Below we will present some outstanding parameters in this aspect.

by Juan Manuel Álvarez*

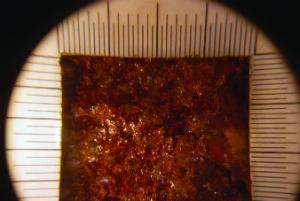

Corrosion inspection reports are usually limited to the product that is detected by visual inspection. (Photo 1 - cover). This criterion does not allow to visualize its origin, unless the type of corrosion is identified, which will determine the mechanism by means of which the product has been generated (Photo 2).

If the identification of the type of corrosion is additionally reported the level of affectation to the material in the place where it occurs, you can visualize the corrosivity regarding the relationship between the resistance of the material and the aggressiveness of the environment that originates the reaction for the corrosive formation that is intended to be reported (Photo 3).

The environment can be quantified according to the variables that make it up: temperature, humidity, pH, pressure and mechanical work that occurs on the affected structures or surfaces.

Temperature is the catalyst for any chemical reaction, which is why it is vital to determine its behavior and participation in the generation of the corrosion product. Service temperatures, safety temperatures, storage temperatures, heating or cooling speeds, temperature cycles or even thermal shocks can help establish the origin of corrosion and even find the remedy or recommendation so that the phenomenon does not recur for a long time (Photo 4).

Humidity represents the electrolyte that gives rise to the electrochemical circuit responsible for most types of corrosion, which is why its concentration and identification must be known. The estimated value of humidity comprises both the vapor system and the liquid system, as well as the concentrations of aqueous solutions and their behavior with respect to concentration variation, such as evaporation, and even volatility when presented (Photo 5).

Establishing the pH helps to conceptualize the type of reaction that is carried out for the formation of the corrosion product and the interference for the selection of the material in that type of environment. The concept taken from the behavior of materials and even alloys in relation to Pourbaix diagrams proves this. The reactivity of the materials and the behavior of them with the variation of the pH make that for the selection of materials, and mainly of control methods this is a determining data of the medium for calculation purposes (Photo 6).

Pressure involves both the barometric pressure of the environment and the behavior of fluids with respect to pressure and as they are handled both inside transport elements (pipes) and vessels (tanks), the movement of fluids and their variation are also considered within this variable (Photo 7).

The mechanical work that occurs on the affected structures or surfaces specifies the probability of one type of corrosion or another occurring. This depends on whether it is cyclical, internal, or if there are section changes such as joints, assemblies or overlaps with dissimilarity of materials that accuse reasoning from the design. This always leads to the selectivity of the type of reaction that is presented. The velocity of the fluids and their Reynolds number: whether laminar or turbulent flow, determines different types of corrosion caused by different mechanisms (Photo 8).

After analyzing each of the variables in each corrosion report, the evaluation of the corrosion control system that has been applied may be considered, which will determine the reason for the failure, either for qualitative reasons (type of coating, for example) or specification or compliance with standard (type of material, chemical resistance of the coating, effectiveness of the inhibitor, porosity of the protective film - Photo 9).

Therefore, it would be recommended to have knowledge of issues related to the aforementioned variables, not only to report corrosion problems, but in order to recommend the procedure for their treatment or the change of corrosion control method (Photo 10).

This is the real difference between corrosion treatment and corrosion control, since those who work in corrosion control must have multidisciplinary knowledge such as:

Materials.

Structures.

Efforts.

Fatigue.

Welding.

Non-destructive testing.

Coatings.

Meteorology.

Chemistry.

Fluids.

Other complementary knowledge.

The criterion required in corrosion inspection for correct decision-making is an important step in the durability of materials in compliance with structural work or in service, and in the durability of the protection provided by control methods (Photo 11).

The reliability of a structure over the years is a reflection not only of the frequency of inspection and maintenance carried out, but also of the quality of inspections and reports, as well as the procedures that are executed and the recommendations that are generated (Photo 12).

The next article will deal with the topic of corrosion control and prevention methods. Until next time!

* Juan Manuel Álvarez is a Consulting Member of the technical committees of NACE International, Member of A.S.T.M, of ACICOR (Colombian Association of Corrosion Engineers), of ASCOR (Colombian Association of Corrosion and Protection), of ACOSEND (Colombian Association of Welding and Non-Destructive Testing), of ICONTEC (Colombian Institute of Technical Standards), of the technical committees of END, Welding, Coatings, Fuels and others. He is also a university professor and lecturer. You can write to the e-mail: [email protected]

Leave your comment