This is an interesting topic that deals with the way in which a dominant technology headquarters before the arrival of a new advance that allows to improve operations. Let's see how it applies in our industry.

This is an interesting topic that deals with the way in which a dominant technology headquarters before the arrival of a new advance that allows to improve operations. Let's see how it applies in our industry.

by José Tomás Rojas*

By technological disruption we mean an advance that breaks with traditional schemes in the way of doing things, call them formulate, produce, distribute or market a product. A technological disruption sets a new set of rules, sets a trend, marks a novel way of doing business, and in general, displaces, sometimes in its entirety, the technologies that preceded it.

As an example of this concept, I like to cite the displacement of the three-piece container, by the two-piece container, in the beverage industry, as it constitutes the perfect example in terms of a technological disruption, which included not only the replacement of the packaging, but also radical modifications in product engineering, production processes, marketing schemes, and, of course, important changes in paint technology, which I was able to witness first hand, since I participated in my country as a Formulator in the development of the painting technologies applicable to these processes.

Three-piece containers

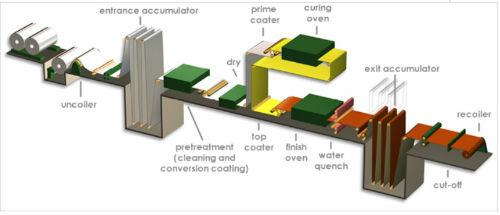

Basically, a three-piece container is made of tinplate. It consists of lid, body and bottom, elements that are manufactured from a tin coil, which must previously be subjected to various surface treatments and paint processes, in stages, with bakable coatings of the phenolic epoxy type for the interior, and polyester or acrylic for the exterior, including lithography. The processes in general are continuous, that is, the coil is unwound, cleaned, paints one side, bakes, paints the other side, bakes and rewinds, in a single process. See Fig. 1.

All applications are made with rollers, in a process that is usually quite cumbersome, especially because of the number of stages and controls that must be established to maintain the film thicknesses in the sheet (they are usually very low).

The space required in the plant for the assembly of these large lines, and also very good controls are required for the solvent vapors that emanate from the lines. Keeping these lines in optimal operation is practically an art, and they depend a lot on the criteria and expertise of the operators in charge of keeping them running. It should be noted that this application process is still widely used in the packaging industry, appliances, metal ceilings, among others.

Fig. 1. Application to rollers. unwinding, surface treatment, drying, primer, curing, finishing, curing, rewinding, cutting.

Once the coil is painted, it is cut into sheets, and taken to a cutting and die-cutting process. Subsequently, the body and bottom are assembled through welding, and this assembly, accompanied by the lids, is sent to the customer, who will pack the corresponding products in them.

Two-piece containers

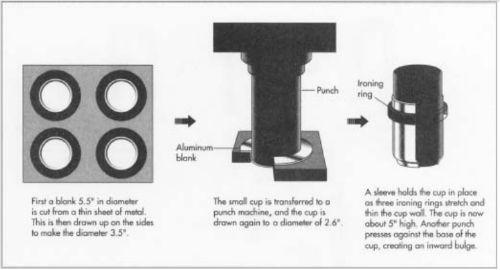

The two-piece container is made of aluminum, from a single piece of this metal. By means of a drawing process, the bottom and the body are manufactured in a single stage, without the need for welds (Fig 2). After washing, the set is ready for the painting phase, which is water-based, also bakable. The savings in process space and time against two-piece technology is evident.

Fig. 2. Manufacture of two-piece aluminum container.

The application of the coating is done by automatic gun (Fig. 3), with special designs, and it is somewhat surprising to observe the speed at which these equipment works. The process is so fast that it is difficult to follow it with your eyes. The paint that was developed for this purpose, in particular the interior coating, consisted of a system of the epoxy type reducible in water, with a very precise Rheology, to allow the application, at high speed, of a homogeneous film, of low thickness, transparent, of high chemical resistance, hard, but at the same time flexible.

That the product was reducible in water, also gave it many advantages from the point of view of environmental controls and quality of the workspaces. The productivity of these lines is amazing, and also the aesthetics of the new cans was very well received by the market. The container was also very functional, thanks to the incorporation of an "easy opening" ring that allowed access to the contents of the container without much effort.

Fig 3. Application of paint in two-piece container.

I witnessed the implementation of two-piece packaging technology, as a formulator of the inner and outer lining, and also, because at that time I collaborated as a translator of the manuals for the die-cutting machines, and from that experience what amazed me the most was to observe how this new technology practically ended the industry of three-piece packaging for beverages, also affecting the whole set of industries that served these companies, including paint companies, which had to face a very drastic reduction in their sales of industrial paints.

Some companies were able to reconvert to the new technology of paints for two-piece containers, as was the case of the company where he worked, thanks to an agreement with an American company that had already achieved development. Of course, this agreement involved a very important disbursement in the payment of royalties, training of technical personnel, acquisition of process equipment and purchase of new raw materials.

However, the investment was a success, and the products that were developed worked very well on the new paint lines. Other companies in the sector, however, limited to adapt to the new scheme, saw their sales come to a minimum, and others even disappeared.

Technological disruption is not something that happens often. Particularly in the field of paintings, advances occur incrementally, cumulatively, which in a certain form of time must be adapted to changes, without major trauma. However, we must be very aware of the advances, because we do not know if the next technological disruption that alters our way of doing things already appears around the corner.

* José Tomás Rojas. JTROJAS Pinturas, F.P. You can send your comments to the email [email protected]

Leave your comment