Certainly to achieve "corrosion control" in a structure it is essential to determine in which "environment" the structure is in service, and even for which environment the installation of a structure is contemplated; that is, from design and construction.

By Juan Manuel Álvarez*

The environment must be identified and assessed from the point of view of the different variables to which the material of the structures will be exposed. Therefore, the environment itself comprises:

Humidity

Temperature

pH or chemical information

Pressure

The mechanical work that the material of the structure fulfills

The exposure or reaction time

Each of the variables of the environment is determined by:

Humidity: represented by relative humidity and condensation, wetting capacity, rainfall, etc.

The temperature: represented by both the environmental and surface temperature, as well as the heat gained or lost, so the daily thresholds must be known, by season or by season.

The pH: refers to all chemical information that is transported to the surface of the materials of the structure by the different vectors; such as air that carries compounds or molecules to the surface.

Example: the different qualities of water that, due to their different composition, and even concentration, vary the pH (acidity or alkalinity). Therefore, the pH of the environment will depend on the chemical information dissolved or present.

Pressure: it is represented by the natural atmospheric pressure and by the pressure supported by the material, both internal and external (grain behavior and reactivity in exposed areas).

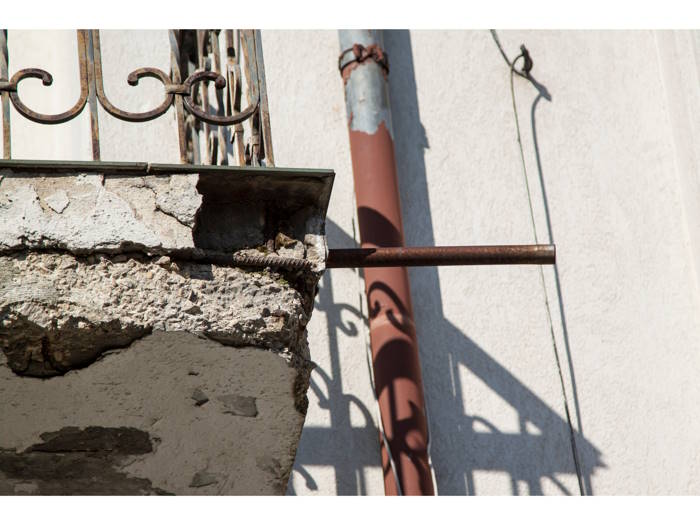

Mechanical work: refers to all those mechanical stresses to which the material of the structure is exposed; cyclical or non-cyclical, which generate types of corrosion due to their participation in formation and propagation.

The exposure or reaction time: refers to the times that are added by exposure of the material of the structure or by reaction with the material of the structure, either with humidity, with temperature, with vectors, with pressure, or with any mechanical work.

In such a way that this variable allows quantifying the affectation by formation of corrosion products, even preventively, or help to control through the trend as corrosion speed.

If we start by reviewing the mechanisms that can be used for corrosion control, we can show why it is essential to determine, know or monitor the environment. See:

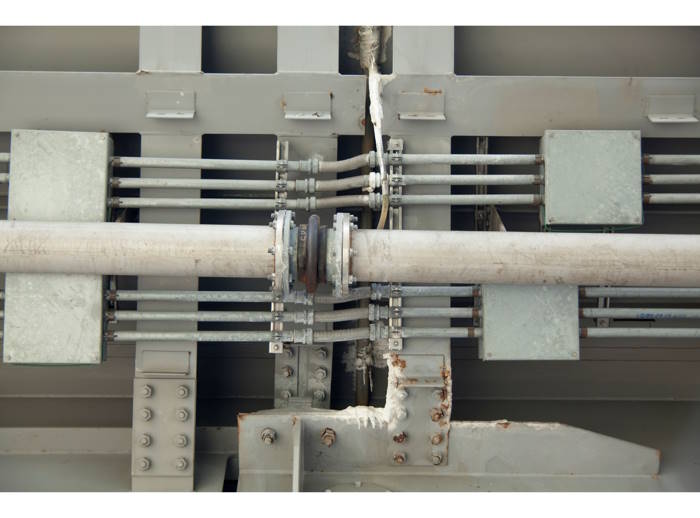

Design of structures and components: important to determine the environment, the probability of condensation, drips, runoff, apozamiento and other forms of presence and contact with electrolytes.

Material selection: the environment determines the reactivity according to the material with which it is in contact; this is how the electrochemical series, the galvanic series and the Pourbaix diagrams determine the corrosivity or reactivity based on the relationship between material and environment.

Passivators: In itself, passivators are applied and designed according to the surface material with which it comes into contact to form the passive protection film.

Coatings: the environment is the first criterion for selecting coatings, so that the correct selection of coatings establishes the durability of the protection from the resistance of the coating in the environment to which it is exposed in service.

Cathodic protection: either by sacrificial anodes or by printed current, the assessment of the environment is taken into account in the calculations and design of cathodic protection, which is why it is decisive.

Cathodic protection: either by sacrificial anodes or by printed current, the assessment of the environment is taken into account in the calculations and design of cathodic protection, which is why it is decisive.

It should be borne in mind at all times that environments are changing, which is why they must be monitored.

Environmental monitoring is a tool that generates statistical information that, if well managed, allows us to determine the corrosion control that may be achieved through criteria related to the variables. But, at the same time, it allows to establish the durability to which the control mechanism or mechanisms used for corrosion control can reach.

Thus, determining the type of environment and knowing or classifying it through its variables is of great importance as a criterion in relation to corrosion control.

Nowadays the environments have been standardized and classified, which allows to have a tool with endorsement and concept of quality, which helps when it is properly established based on the proper interpretation of the information that determines the standard in relation to the correct gear with respect to the physical environment and its behavior, where the structure is in service.

The classification standard is ISO-12944, which basically takes into account the variables of humidity, temperature and pH.

The ISO-12944 (2018) standard determines the classification of environments as:

C1. Dry or cold with very low contamination.

C2. Temperate environment of low pollution.

C3. Temperate with medium pollution, tropical with low pollution.

C4. Temperate with high pollution, tropical with moderate pollution.

C5. Temperate and subtropical with very high contamination and/or significant effects of chlorides.

CX. Extreme industrial zones, offshore areas.

IM1. River installations and hydroelectric power plants.

IM2. Submerged structures without cathodic projection.

IM3. Buried structures.

IM4. Submerged structures with cathodic protection.

Based on the above, each of the variables must be taken into account in the assessment of the environment. In such a way that for the design and fulfillment of a Corrosion Control program is taken into account with respect to each type of material and even in each structure, even if they are theoretically in the same environment.

For example, in the same area there may be several structures with the same materials, but not all reach the same temperature gradient, or the same vectors, or rain on all sides of the structure.

On the other hand, several structures may be present in the same exhibition environment, but with different materials, machinery or structures inside with different internal microenvironments in the same structure.

All these possible variables must be taken into account to determine, know or monitor in each of the microenvironments (or environments within the same structure).

The success of achieving the best corrosion control and achieving control at the minimum or predicted corrosion rate for the expected durability of the structure in service depends on the environment. Hence the importance of determining, knowing and monitoring the "environment".

The success of achieving the best corrosion control and achieving control at the minimum or predicted corrosion rate for the expected durability of the structure in service depends on the environment. Hence the importance of determining, knowing and monitoring the "environment".

In this cycle of articles aimed at corrosion control, as stated since the first edition, after having developed the topics of Corrosion Control Mechanisms and Environments, it is considered complementary and as a purpose of design and control to deal with the topic of Durability.

In the next edition, the theme of "Durability" will be developed, related to the control of corrosion in structures.

As always, I wish you a good aging and every success in your work.

*JUAN MANUEL ÁLVAREZ RODRÍGUEZ

Designer for Corrosion Control, Certified Coating Inspector, Corrosion Technician and Marine Coating Inspector (NACE International, the Corrosion Society)

A.S.T.M. member of the committees of corrosion, paints and coatings, fuels, general

aviation, adhesives, nondestructive testing, and composites.

Certified Instructor ICAO (International Civil Aviation Organization).

Inspector in Non-Destructive Testing.

Instructor, lecturer and columnist

Specialist in Metal Structures and Composite Materials

Juancorrosion.com [email protected]

Technical Manager of Corrosion, Control and Quality, Advisory Services, Inspections and Training for Corrosion Control and Prevention

Buenos días, Álvaro. Muchas gracias por su lectura y amables palabras. Saludo de vuelta.

Saludos.